February 28, 2019

Screen Printing Vs. DTG: A 10-Round Battle

As direct-to-garment digital printing has gained popularity and affordability, the question that arises more and more often: How does DTG printing stack up against traditional screen printing? In other words, what’s the best T-shirt print method?

I’m here to answer that question – in the form of a 10-round fight for print method supremacy. Each round will cover a different facet of custom apparel printing, including vibrancy, color matching and durability. Whichever print method wins the most rounds takes home the championship belt. And remember kids, nobody is getting punched in the head. It’s just a metaphor.

Direct to Garment: The Scrappy Newcomer

DTG has been around barely 15 years, but in that time technological advancements have come at a rapid-fire pace. Each year, this print method gets faster, more affordable and produces higher-quality prints.

The bar to entry for most printing companies is still fairly high. A decent professional machine can cost anywhere from $15,000 up to $800,000. But as business investments go, it’s a good one: A company can start taking low-quantity, on-demand orders without the typical setup cost and effort of screen printing. In fact, most online on-demand printing companies are using DTG printing machines.

Screen Printing: The Defending Champion

Screen printing has been around forever (at least since the Song Dynasty in China circa 1000 AD), but exploded into modern culture during the 1960s with the popularity of Andy Warhol’s artwork, the printed T-shirt trend and the invention of the rotating multi-color screen-printing machine.

A steady stream of technological advancements has improved quality and efficiency, but the central concept remains the same: Push ink through a mesh stencil onto fabric (or “the substrate” if you want to sound like an expert).

Screen printing remains the most widely known and widely used form of decorating custom apparel, but DTG is fast becoming a contender. So, does screen printing still hold the championship belt, or is it time for the newcomer to take the title? Let’s find out.

Round One: Vibrancy

Screen printing comes out aggressive with the one-two punch of saturation and brightness. When you want your design to stand out and really pop off the shirt, you go with screen printing. DTG printing has come a long way, but still has a slightly duller appearance when you compare the two.

What accounts for the difference? Traditional screen printing uses plastisol ink (typically composed of PVC particles suspended in a plasticizing emulsion), which are extremely opaque and come in a wide range of exact colors, whether right out of the bucket or with a custom Pantone mix.

A dramatic difference in color vibrancy: screen printing (left) vs DTG (right)

Digital printing, on the other hand, uses water-based inks, which lack the opacity and vibrancy of plastisols, especially on darker garments.Even though DTG machines can provide a bright underbase (plastic particle pre-treatment and titanium dioxide white ink) which improves the vibrancy, the final results are still lacking, compared to screen printing.

DTG relies on process printing, or the CMYK (cyan, magenta, yellow and black) color model to make various shades. While the colors themselves are bright, they’re also semi-transparent so they can be blended more easily. Fluorescents and other vibrant colors outside of the CMYK color gamut are possible using plastisol screen-printing inks.

The winner of this round is clear. Or should I say opaque?

Round Two: Color Blending

DTG comes out swinging in the second round with excellent color blending. What do I mean by color blending? It’s the ability to create smooth gradients and a range of colors by blending a lesser amount of colors. And that’s exactly what DTG printers were made to do.

A DTG machine is essentially a giant inkjet printer, similar to what you might have at your home or office, but it’s designed to print on T-shirts and other garments. When printing DTG, we call it “full color” but we’re actually using four colors (or six like on the more advanced models). It works using process printing; the four colors of CMYK blending to create a spectrum of colors.

When it comes to gradients or precise blends like those needed for skin tones, digital printing is more reliable than screen printing. And with little to no setup.

Screen printers can take spot colors and create a spectrum using a technique known as “simulated process.” But the setup involved makes it less efficient, especially for smaller orders. And the results can be mixed.

With DTG, the inks are water-based and more transparent than plastisol. This allows the ink to overlap and blend, making beautiful, smooth gradients, and giving DTG the winning edge in this round.

Round Three: Color Matching

Screen printing comes back strong with its precision color-matching capability.

Using the beloved Pantone color-matching system, we can duplicate any color a client needs. That includes those outside the range of CMYK, super-saturated colors and specialty inks.

Matching colors accurately is especially important when it comes to corporate branding. Many companies have brand guidelines that specify Pantone colors. If you try to match those colors with DTG, they’re almost always going to be off. The primary reason is that the underbase isn’t opaque enough, so the shirt color bleeds through. Darker shirts and color shirts can easily become a problem when trying to color match.

Pantone matching can be done with process inks and specifically with inkjet printing on other printing media. And several DTG manufacturers claim they can Pantone match – but only within the CMYK gamut. More advanced DTG machines have added slots for two extra colors: bright green and bright red. Still, it doesn’t make up for screen printing’s ability to print a range that includes every color on the planet.

Sure, there are colors that are out-of-gamut for screen printing as well, but overall, its gamut is much bigger than DTG’s. This round is no contest. When you absolutely need to match exact colors for your brand, you go with screen printing.

Round Four: Details

In the printing business, detail is the smallest parts of the design, which could include fine lines, small type, textures or tiny elements. When it comes to screen printing, it’s always about “holding” detail. If you’re not holding it, you’re losing it.

There are several factors that affect screen printing detail:

- Screen tension

- Squeegee sharpness

- Pressure and speed of ink application

- The surface properties of the material being printed

- The viscosity of the ink

- And the biggest one of all: ink gain or ink spread.

Yeah. It’s a lot to deal with.

Screen printing has visible dots. DTG’s dots are so small you can’t see them. If an image is photographic or has gradients, screen printing requires halftone dots. You might remember seeing them if you ever looked at a comic book with a magnifying glass. Developed in the 1800s and first used in newspapers to reproduce the tonal range of photographs, halftones soon became ubiquitous in screen printing. The look is such a well-known part of the aesthetic that artists (think American pop artist Roy Lichtenstein) often use oversized halftones for a stylistic effect.

Most halftones for screen printing are output from a raster image processor (RIP) program at anywhere from 30 to 65 lines per inch (LPI) before being burned to screens. The lower the LPI, the bigger the dot. Even at the higher LPI, these dots are visible if you look close enough. And if ink gain becomes a problem, each dot is going to spread out a little bit. Making it bigger and more visible.

DTG uses halftones as well, but these digital machines can print up to 1,200 dots per inch (DPI), and use diffusion dither. To get extra technical, this is a frequency-modulated halftone instead of an amplitude-modulated halftone. It can sometimes result in a grainy look, but a much better reproduction of small details.

Round Five: Durability

Durability is something DTG has always struggled with. In the early days of DTG, you would be lucky to get 10 washes out of a T-shirt before the colors would start fading. Nowadays, you can get many more. How many? Like most things in this business, it depends. The quality of the machine, the inks used to print, the pretreatment, the underbase and the curing all factor into it.

It also depends on how you wash it (stay away from hot water, harsh detergents and long dryer times). A quality DTG print can potentially get dozens of washes before it starts fading.

Done correctly, screen printing doesn’t have this durability problem. Sure, if the ink isn’t applied or cured properly, even plastisol can fade or deteriorate. But we all have that shirt in our drawer from the family reunion 20 years ago that’s still holding on.

Round Six: Comfort and Feel

By comfort and feel, I mean a few things:

- If the ink clogs up the fibers. This can severely reduce the breathability of the fabric, causing what’s affectionately known as a “sweat patch.” You can imagine what that is. Think about someone running a 5K in the summer with a thick, solid layer of plastic covering their chest.

- How heavy the print the feels on the shirt. If the ink is too thick, it can weigh down the front of the shirt, or wherever the print sits. This is especially important for all the lightweight blends so popular today.

- If the texture is rough on the skin. You don’t want a print to feel like sandpaper. You don’t want to give someone road rash from hugging them.

This feel is also known as “hand” in the screen printing business. If the request is for a soft hand, it usually means to use discharge or water-based ink. If using plastisol, it means to thin the ink down with an additive to make it smoother and more lightweight on the shirt.

Distressed-look screen printing can also create a softer hand by reducing the amount of surface area the ink occupies and breaking it up so it’s more flexible. But adding this style is up to the customer, and it won’t look right on all designs, so this saving grace only applies to particular orders.

Most regular screen-printing jobs will be printed with a normal layer of ink, and on dark garments it will be two layers of ink, counting the required underbase. Plastisol tends to be heavy on the shirt, one of the reasons it’s so durable.

So when it comes to comfort and feel, DTG comes out on top.

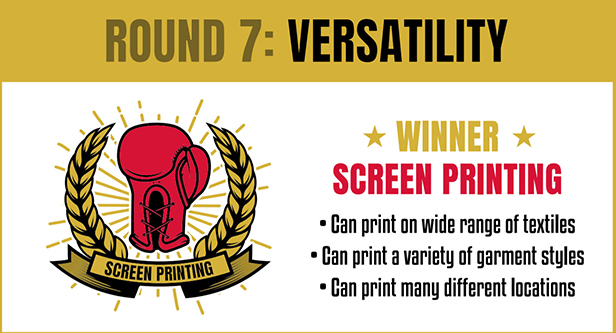

Round Seven: Versatility

Versatility in this context is the ability to print on a variety of textiles, as well as a variety of garment styles, print locations and placements. DTG is somewhat limited in this category.

Textiles: Although DTG works with a wider variety of fabrics than ever before, the number-one choice recommended is 100% cotton. Newer systems advertise printing on all kinds of fabric, but these systems aren’t yet widely used in the industry.

Typically, DTG has trouble with 50/50 blends, and performs poorly on polyester. It doesn’t work on moisture-wicking fabrics at all without special treatment, and even then it’s not recommended.

Also, the color of the fabric can be a problem, mostly due to dye migration. This happens when the garment dye bleeds into the ink and discolors the print. And digital printing on fluorescent colors is a no-go.

Screen printing, on the other hand, works on cotton, blends, polyester, canvas, denim, performance and moisture-wicking fabrics like rayon. And, of course, any color garment your heart desires. It’s easier to tell you what fabrics you can’t screen print on.

Garment styles: If you’re only printing on the basics like T-shirts and hoodies, you can DTG all day long, but if you want to print on hats, for instance, your best bet is switching to screen printing (or embroidery).

With DTG, it really depends if the printer has a specialized platen (or if there’s even one available) that fits the garment location you’re trying to get printed. This is also true for screen printing, but there are many more platens available.

Print locations: Screen printing is also less limited when it comes to locations. As long as the printer can somehow position the garment on a platen, it can be screen printed. This goes for pant legs, the hoods of sweatshirts, on-the-pocket prints, side prints, etc.

DTG, in certain cases, may not be able to reach a particular placement within the location to be printed. For example, if you wanted your logo to be placed 1 inch from the collar of an upper back location, DTG may not be able to get that close to the seam.

Much of it depends on the capabilities of the print shop you’re using, but the bottom line is that screen printing has fewer restrictions.

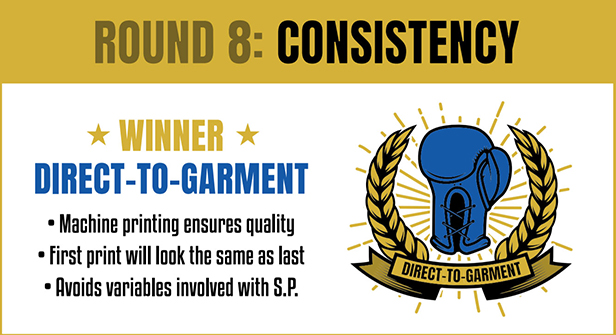

Round Eight: Consistency

Screen printing can be consistent, but only if the job is set up perfectly and each item is printed in exactly the same way. A tall order. The screen-printing process has many variables. Screen tension, clogged mesh, ink viscosity, dot gain, flash dryer temperature, squeegee sharpness, squeegee pressure, squeegee angle, registration, placement. On their own, each of these can make a difference; combine them, and chances are, there’s going to be some variation, especially when printing halftones. The last print of the run is going to look a bit different than the first print. It’s just how it goes with screen printing.

DTG, on the other hand, crushes it in the consistency department. Because a machine processes a digital file and prints directly onto the shirt, there are almost no variables to worry about, except maybe the placement of the garment onto the platen. Consistency is DTG’s middle name.

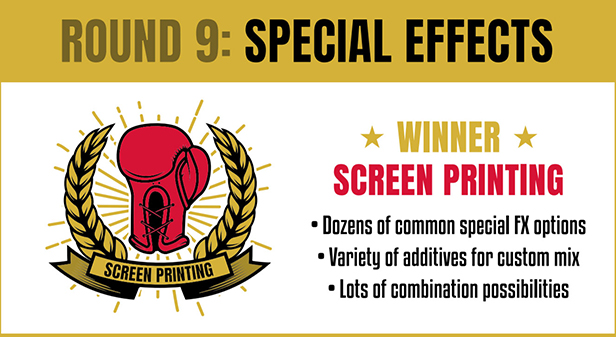

Round Nine: Special Effects

Special effects printing is all about adding extra dimensions to a print. From raised print to textures to shines and sparkles and glows, there’s a specialty ink or additive that can do it. The best part is you can combine many of these for creations that are limited only by your imagination (and budget).

For example, using puff with high-density and suede, you can create a faux tackle-twill, mesh or even embroidered look, complete with fake stitching. Or, you can stack high-density until you get a print so raised it looks like an appliqué. This can be really cool for a small sleeve logo.

Examples of specialty inks and additives:

- Water-based: Absorbs into fabric for a very lightweight and soft print.

- Discharge: Chemically removes the dye from the pigment of the fabric.

- Puff: This additive expands while being cured, for a soft, raised feel.

- Fluorescent: Very bright neon colors, also known as “day glow.”

- Metallic: Popular ink for a shiny look. Typically in gold, silver or copper.

- Glitter: Contains glitter for a sparkly look, often combined with clear gel.

- Glow in the dark: Almost clear, light-activated ink that glows in the dark.

- Suede: Similar to puff, but creates a soft and fuzzy texture to the surface.

- High-density: Creates raised layers of rubber-like ink for a 3-D print.

- Soft hand: Additive for reducing the thickness of ink for a softer feel.

- Clear gel: A thick glossy coating that can be used in combination with others.

- Shimmer: Creates a reflective, iridescent shine.

- Crackle: Splits and cracks during curing for a naturally distressed look.

- Cork: Similar to puff and suede, but the final product has a cork-like texture.

- Plasticharge: Combines the best of plastisol and discharge.

This isn’t a comprehensive list, only the most common. There’s definitely some even crazier stuff out there. Printing a specialty job can be a trial and error at first, but once you get it, successful results are super impressive and satisfying. Screen printing specialty inks can elevate a T-shirt design like nothing else, and significantly increase the value for resale.

DTG has been making a few in-roads on the specialty ink front, but nothing that is widely available or as easy to accomplish.

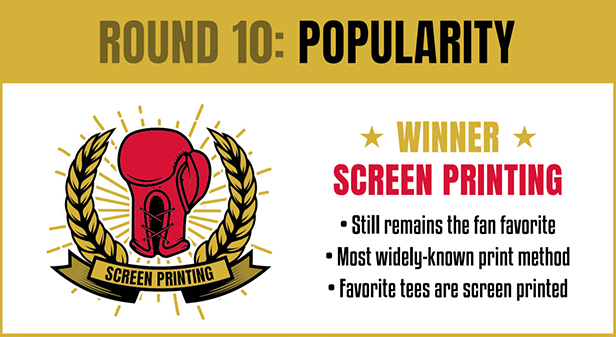

Round 10: Popularity

You might be asking: Why is popularity a factor? People typically want what everyone else wants. So sticking with the popular option is a good idea when you’re creating shirts for an employee program, a promotional giveaway or especially to be sold at retail.

When people think T-shirts they think screen printing. Once DTG technology becomes more advanced, and more ubiquitous, to the point where most people can’t tell the difference, then popularity might no longer be a factor. Until then, screen printing remains the fan favorite.

And the overall champion is ...

***

Imri Merritt works in art, design and marketing for Rush Order Tees, a division of Printfly Corp. See the original version of this story on the Rush Order Tees blog.