July 10, 2017

How to Care for your Apparel Decorating Equipment

Follow the manufacturer’s maintenance schedules to keep your screen-printing machines and equipment in top working order.

Regular maintenance is critical to the performance and longevity of any machine. Follow manufacturer’s instructions and regular recommended maintenance schedules to keep your equipment in top working order. Just as you wouldn’t think of driving a car without motor oil, don’t neglect your presses, dryers and other machines critical to your business and its success.

St. Louis Print Co. has seven automatic presses, four manuals, three dryers, one direct-to-screen, four air compressors and one screen-rinsing unit, and each has its own maintenance schedule, says owner Terry Keeven. His shop ensures optimum performance by religiously following the manufacturer’s instructions and schedules. “If you neglect to run routine maintenance on your equipment, it will eventually start to let you down,” Keeven says.

TAKEAWAY TIPS

1. Make time for maintenance. Regular maintenance and cleaning to remove dust and ink is essential to keeping equipment running correctly. Keeven says he has staff in weekly for maintenance and upkeep routines.

2. Grease ports and clean filters regularly. “Each month, we remove all dust from the fans that keep the motors and electronics cool,” Keeven says.

3. Pay attention to screen pop-up notices. Some equipment will alert users to maintenance issues and other problems with pop-ups on their monitors. Don’t ignore these signals – they’re there for a reason.

4. Don’t forget your other equipment. On conveyor dryers, clean the filters each week, grease and check grease ports, and vacuum the vents to prevent dust and ink buildup. Keeven also recommends cleaning air compressor filters each week and changing their oil and filters every six months. To clean a screen-rinsing unit, like the Eco Rinse, begin by draining the water. After you clean the filters and scrub out the machine, you can refill it with fresh water. Direct-to-screen equipment needs weekly cleaning of all print heads, wiper blades and ink trays.

Product Pick

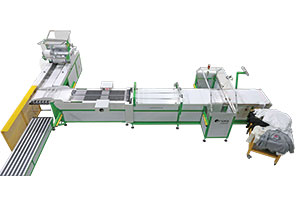

Solve packing and folding issues by adding automated folding and packing equipment to the line. Ryonet Corp. (asi/528500) offers ROQfoldworks and ROQfold, ROQstack and ROQpack, designed to fold, sort and package any type of apparel, allowing one operator to pack up to 800 garments an hour. Bulk folding of up to six garments is also possible. The equipment stacks up to 24 folded shirts, and a second operator can remove each stack for boxing. Visit www.screenprinting.com.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.