March 29, 2018

Hat Tricks: Embroidery Digitizing for Caps

Digitizing for caps presents significant challenges, including the dreaded seam that runs down the middle of many.

From the cursed seam running down the middle of many caps to the lack of methods for secure stabilization, digitizing for and embroidering on caps can present significant challenges to both the new and well-seasoned embroiderer alike. Here are some tips on handling some of the biggest issues with caps.

Height restriction: As a general rule, logos programmed for caps cannot exceed 2.25 inches high. While this number isn’t set in stone, it’s a good rule of thumb to start. There are some equipment manufacturers that say they have sewing fields as high as 3 inches. This may be true, but it’s not the machine alone that determines how much vertical space is available for embroidery. The construction properties of caps are different depending on hat styles; think low-crown, six-panel unconstructed versus a five-panel constructed cap. This doesn’t even begin to address the height restrictions of products like visors (usually not to exceed 1.5 inches) or bucket caps, where all bets are off depending on the product. Digitizers should ask the client what kind of hat a logo will be going on and the available space for embroidery.

Furthermore, be aware of mechanical issues that may come in to play, and be prepared to offer the client some insight. For example, most hat frames will allow a design to be sewn quite large. However, as the design reaches the crown of the cap (if you had X-ray vision, you could see this happen), the throat plate of the embroidery machine will come in contact with the inner crown of the cap and cause the cap frame to move. Once this happens, its’ game over. It’s not the programmer’s fault, but it’ll look like it is.

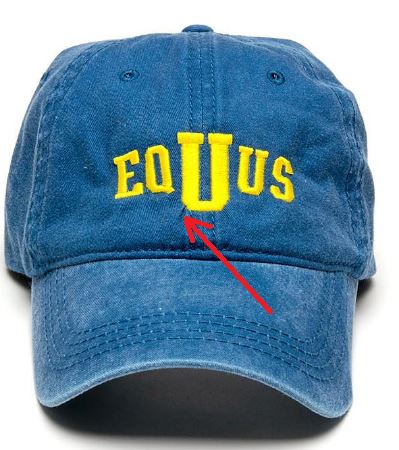

Cap technique: For the most part, cap logos should be embroidered from the bottom up and whenever possible center out. It’s very difficult to frame caps (especially unconstructed caps) with the same type of stability as flat garments. Because of this, loose fabric has a tendency to pucker or get pinched (as shown in the above photo). Programming center out will push the fabric away from the center and provide for a batter chance to keep all material lying flat.

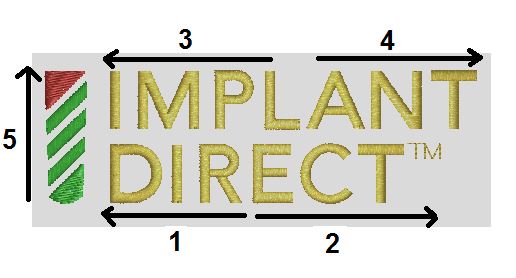

It’s not always possible for the perfect bottom up and center path. When this happens, it’s best to consider the path that will provide the best opportunity for the logo to help the material remain stable with the stitches helping the fabric lie flat. In the pictured Implant Direct example, the text will push the fabric from the center out, leaving a more stable surface on the left side of the seam for the logo to sit flat.

The dreaded seam: The ubiquitous six-panel cap is notorious for the seam that runs down the middle. It causes two big problems that must be considered by the digitizer and customer. Aside from proper technique, it’s critical for the programmer to explain why the seam can cause so many problems.

The middle of the seam is a valley between two high ridges of material. It seems obvious, but many people forget this. If you’re unlucky enough to have a lower-case “i” in the middle of the design, that letter will fall into the valley of the seam and look terrible unless you plan for it.

Also, some caps are made with massive under-seams that dramatically impact the quality of embroidery if not considered. If there’s small text embroidered around the seam, you should ask to see the cap. This might not seem like much, but as a small letter goes up one side of the seam and then down the other, the potential for that letter to get distorted is significant. In the “Hampton” logo, you can see how the seam is affecting stitch quality, starting at the left side of the “M.” This is poor programming. The digitizer should add pull compensation and advise the customer that upping the design size even slightly would dramatically improve quality.

Cap embroidery is tricky, and it requires the highest-quality digitizing. Each project will present its own solution, and you may feel like you’re reinventing the wheel each time you sit down to program a new design. More so than when digitizing for flats, cap digitizing starts with knowing what the logo will be embroidered on. With this information, you’ll know size restriction, the best techniques to use and if you’ll need to deal with a seam. Whenever possible, get a physical sample of the cap you’re digitizing for.

***

Steve Freeman is the managing partner of Qdigitizing.com. He has been a professional digitizer since 1989 and is trained on Melco, Wilcom and Pulse software systems. You can reach him at steve.freeman@qdigitizing.com or (877) 733-4390.