May 26, 2016

How to Avoid Thread Issues With Your Embroidery Machine

Proper thread tension will help prevent birds’ nests and visible bobbin stitches, ensuring a better-quality product and smoother sewing.

Proper thread tension will help prevent birds’ nests and visible bobbin stitches, ensuring a better-quality product and smoother sewing.

Bill Garvin, owner of embroidery machine repair company BG Tech Services, explains the importance of proper thread tension and how to ensure the tension of your machine is correct.

Q: What is thread tension and why is it important?

Bill Garvin: Tension is nothing but a tug of war between the top thread and the bottom. Whichever is the tightest wins. For example, if the top is too tight, then it’ll pull too much bobbin from the bottom, and you’ll see white thread appear on top of the embroidery. If the bottom is tighter than the top, then the bobbin is winning the tug of war and pulls more top thread under the garment. At a certain point, if it’s too tight, the garment gets pulled in the needle plate hole and a bird’s nest occurs.

Maintaining proper tension will improve stitch quality and enable your machine to run smoothly and constantly, day in and day out.

Q: How do you check that your machine tension is correct?

BG: The most common way is to run an “H” test, though other letters work as well. Make sure your columns are at least one inch tall and a quarter-inch wide, so you can easily see stitch quality.

Q: How often do you need to reset thread tension?

BG: If you use a good quality brand of thread, you almost never have to adjust tensions on your machine, as long as you learn to take care of the bobbin case. Specialty threads like metallic and 12-weight acrylics may require some adjustment, however.

Q: What’s the best way to adjust thread tension?

BG: I like to teach customers to set just one needle and run a sample, perhaps sewing out the letter “H.” From there, adjust the top slightly if necessary, and the bobbin case. Run another sample on needle one to make sure everything looks good. From there, make sure all the tension knobs across your machine are the same. They should be screwed in the same amount, and if every needle is threaded correctly, you should be able to tell by the feel of pulling the thread that each has the same tension. If one feels wrong, there’s likely something wrong with your thread path, and you should rethread the needle. Once all the needles are adjusted, sew the full test, and make sure everything is in a good range of tension.

Q: Any other tips you can share?

BG: Keep in mind that regular bobbin case maintenance is key to maintaining proper tension.

Find the Perfect Color

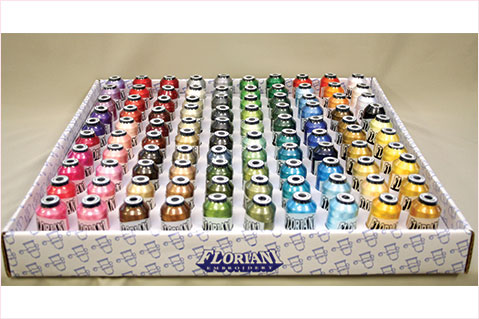

Save on Floriani’s Top 100 Colors

Make sure you have the right thread color on hand with the Top 100 Floriani Thread Colors Set 1 from Floriani Commercial Products. The kit includes high-sheen, high-tensile strength polyester thread in the company’s 100 most popular colors. The thread comes in 1,000-meter cones, and the kit includes a storage box for organization. Among the colors in the set are Mediterranean, light blue, Mars red, pristine blue, pastel blue, ruby red, raspberry rhapsody, twinkle blue, jamocha and light pink.

TAKE THIS CLASS!

Bill Garvin offers day-long classes on topics that include machine maintenance, hooping techniques, troubleshooting design issues and 3-D puff and small lettering at his new Embroidery Training Center in Tampa, FL. The interactive, hands-on classes start at $99 and are limited to eight students each. Visit www.BGTechServices.net or email training@bgtechservices.net.

WATCH THIS!

In this video, Bill Garvin demonstrates the right way to set your embroidery machine tension.