May 04, 2017

Playing Matchmaker

The best way to get an exact color match is to purchase an ink mixing system that uses Pantone colors.

Sooner rather than later, a customer will walk into your shop and ask you to match a specific color, meaning you’ll likely need to use a Pantone Matching System (PMS). Many businesses use an exact set of colors in their logos, whether on business cards or T-shirts. When you print for colleges and universities, nearly all your inks will need to be an exact color match for logos, mascots and school names.

Pantone LLC didn’t create their color match system as an altruistic service to the printing industry. Pantone is a for-profit company based in Carlstadt, NJ, and is the recognized standard for color matching in our industry and beyond. When you mix your first exact color match, you’ll become intimately familiar with the PMS book of standardized color, which you can purchase in fan format for around $150. Since 1963, the PMS is how the world has communicated accurate colors.

Since I’ve spent a good part of my career printing licensed collegiate graphics, let’s use the example of a trademarked college logo. If you were licensed to print the Ohio University Attack Cat, the licensing company or university would inform you that the green lettering is PMS 342 and the cat face PMS 728.

So how do you get to those exact shades? Attempting to use colors from your inventory that are close will not be acceptable to any school or business that takes pride in its logos and trademarked identities. And attempting to mix your off-the-shelf colors to make the right color is virtually impossible. The colors will commonly look muddy when mixed together. But a mixing system comprised of plastisol inks will help you to accomplish the task easily.

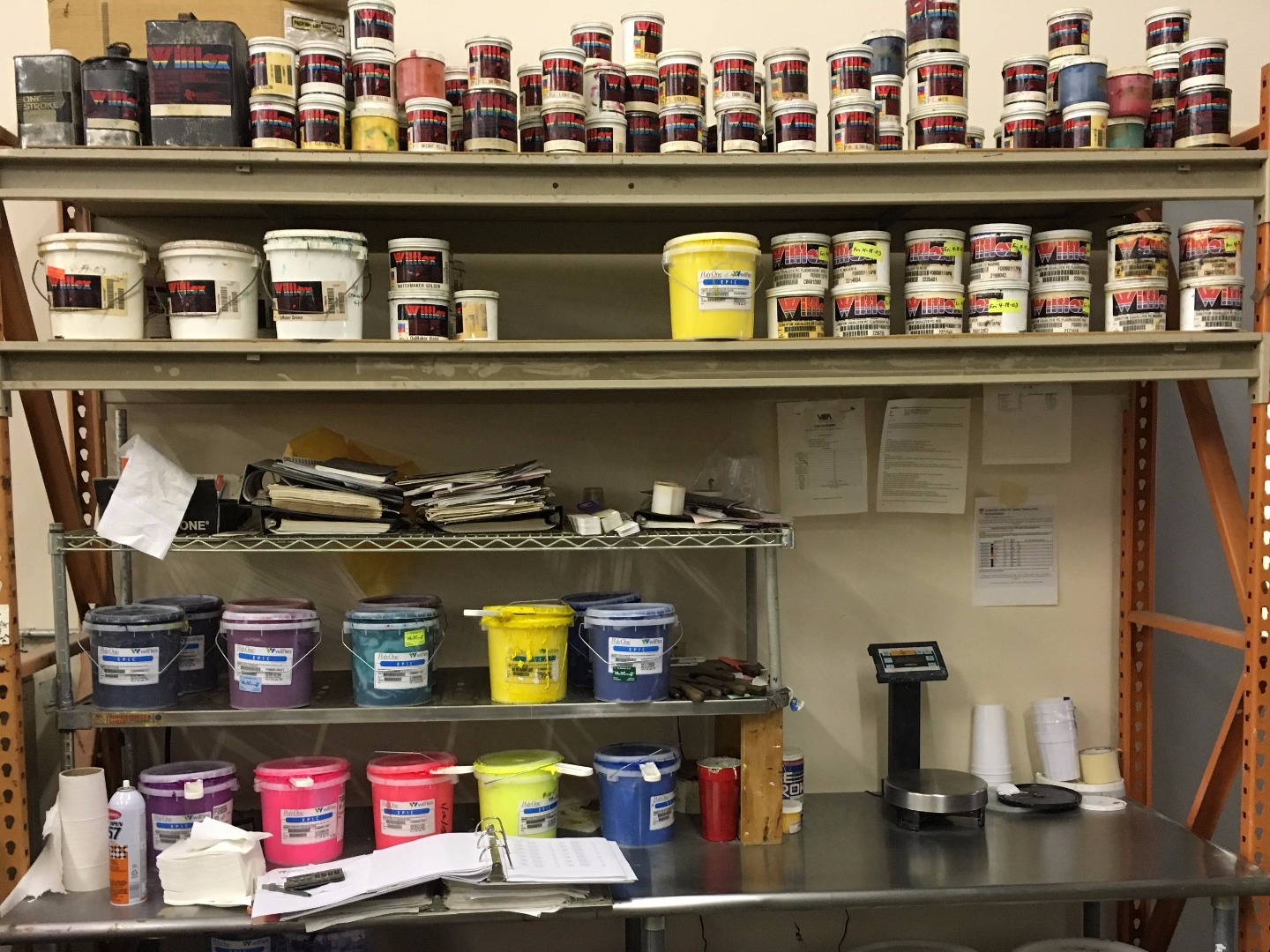

Most ink manufacturers offer a PMS color matching system, consisting for the most part of 15 mixing colors plus a plastisol base. Starter matching systems generally cost around $150. You’ll add larger containers of the colors and base as needed. Along with the ink system, you’ll need an accurate scale. Of course, you’ll need empty containers with lids as well, and plenty of stir sticks at your mixing station.

PMS matching books get a lot of use in the ink room. Photo courtesy Mind’s Eye Graphics, Decatur, Ind.

Ohio University’s trademarked Attack Cat logo features lettering in PMS 342 and a cat face in PMS 728.

The software that comes with your mixing system will allow you to enter a PMS number and denote whether you want to make a pint, quart or gallon of ink. Once you enter this information, the program will give you the formula by weight to create the exact PMS color in the selected quantity. To start, you will place the empty container on the scale, zero out the weight of the container and proceed to add the colors and base according to the formula. If all is done properly and after mixing thoroughly, the ink in your container should be an exact match.

Ink mixing station with scale. Photo courtesy Mind’s Eye Graphics, Decatur, Ind.

Ink mixture on the scale before stirring. Photo courtesy Mind’s Eye Graphics, Decatur, Ind.

Makeup of these systems varies from manufacturer to manufacturer, but work similarly to this description. Check with your own ink supplier for the options they provide. Chances are excellent that the ink brand you currently use will have the option of adding an ink mixing system.

When printing simulated process (using traditional plastisol inks in place of CMYK process inks) you sometimes need to match a color that is difficult to achieve by blending all-purpose plastisol colors. Most separation software programs will allow you to drop in a PMS match color in these situations.

Ink being mixed to create PMS match. Photo courtesy Mind’s Eye Graphics, Decatur, Ind.

Creating exact color matches can be a simple process, with the right tools and adherence to the exact formulations. And chances are, you’ll soon be asked to start color matching in your shop, if it hasn’t happened already.

***

Terry Combs is a 35-plus-year veteran of the garment-printing industry and has managed production shops large and small across the United States. He has written hundreds of management and technical articles for garment-printing publications and spoken at industry events worldwide. He is currently in sales and training with Equipment Zone, Franklin Lakes, NJ, working from Scottsdale, AZ.