October 03, 2016

Understand Your Trimming System

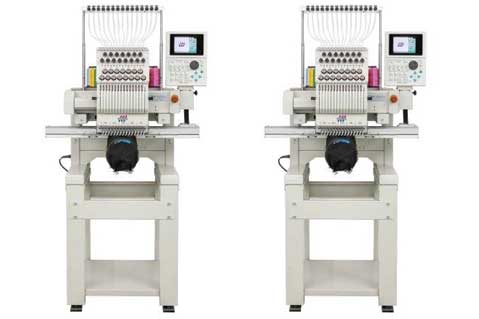

Here’s the sequence of actions involved in your embroidery machine’s trimming system:

1. When the machine is sewing, the trim function begins when the machine detects a trim code from the design. The machine will slow down to allow the trim function to initiate.

2. The picker then engages with the thread loop that has been formed by the rotary hook. This is needed to provide the correct length for the next time that thread is used.

3. The moveable knife comes out to bring the thread forward to the fixed knife. The fixed knife separates the upper thread and bobbin thread.

4. The moveable knife returns to its home position and the selected threads are cut.

5. The bobbin thread will be held in place by the under-thread presser (a thin piece of metal under the fixed knife) for when the machine begins to sew again.

6. The upper thread hook, or “sweep,” comes out from behind the sewing head to grab the top cut thread and put it into the Velcro thread presser, which is also behind the sewing head.

Watch This!

In this video, Bill Garvin, owner of embroidery maintenance firm BG Tech Services, demonstrates how to check the trimmers of your commercial embroidery machine.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.