November 01, 2017

Save Time With Software

An accounting program will help you streamline your invoicing process, but if you’re looking to save even more time, production management software could be the route to go.

These days, everyone seems to be looking for software or an app to improve their life. In the world of embroidery production, there are some excellent software products that can benefit a shop, but before you start shopping, take some time to figure out what you’re trying to accomplish and what kind of issues you’re looking to solve.

For example, if you’re trying to find a way to streamline your invoicing process and capture order details, then you may be in need of an accounting program. Software products such as QuickBooks can provide you with some very useful abilities in terms of managing accounts, billing customers, creating invoices and tracking jobs. Some of these programs are very sophisticated and can provide an unbelievable amount of detail in terms of accounting, but they can also be very difficult to learn because of their complexity. But if all you are trying to do is keep up with your clients and more accurately bill them, accounting software might be the right choice.

On the other hand, if you’re looking for production management rather than account management, then you’ll need to look at software that is specific to the type of decoration you do and that can be tailored to fit the needs of your shop.

With embroidery production, you only make money when the needle is going up and down. When the machine stops, for any reason, you cease to generate revenue. Thus, it’s important that you keep your machine running as many minutes as possible out of every hour. And if you have multi-heads or multiple machines, the need to keep them running is even more critical.

For example, if you had a single-head machine running at 600 stitches per minute (spm), that’s equal to 10 stitches per second (sts). If your machine stops for one minute you lose 600 stitches of production. Ten minutes and you lose 6000 stitches of production. If you happened to be charging $1 per 1,000 stitches (for easy math), you just lost $6 in production time. If you had a six-head, that would be $36. Two six-heads - $72. You see my point. Look at your average machine speed and average run time per hour to calculate your production and downtime costs. It might surprise you how much money lost production is costing you.

Understanding that concept, you can start looking at how to be more efficient so that you can get more out of your machines each and every day. A big part of that is scheduling work so that the downtime of any given machine is as minimal as possible. One of the first things you may learn is that you need to group your jobs in such a way as to minimize machine setup.

For example, run all of your headwear back to back, even when some jobs contain multiple types of products. Pull the headwear out as a sub-job, and run it with the other caps. Why? Because it takes a good bit of time to switch a machine from flats to caps (and back). If you’re doing this multiple times a day, you’re wasting a lot of time. Much better to run one type of product continuously until it’s absolutely necessary to switch over. There are other aspects to consider as well, such as organizing jobs by thread colors so as to reduce downtime associated with changing out threads.

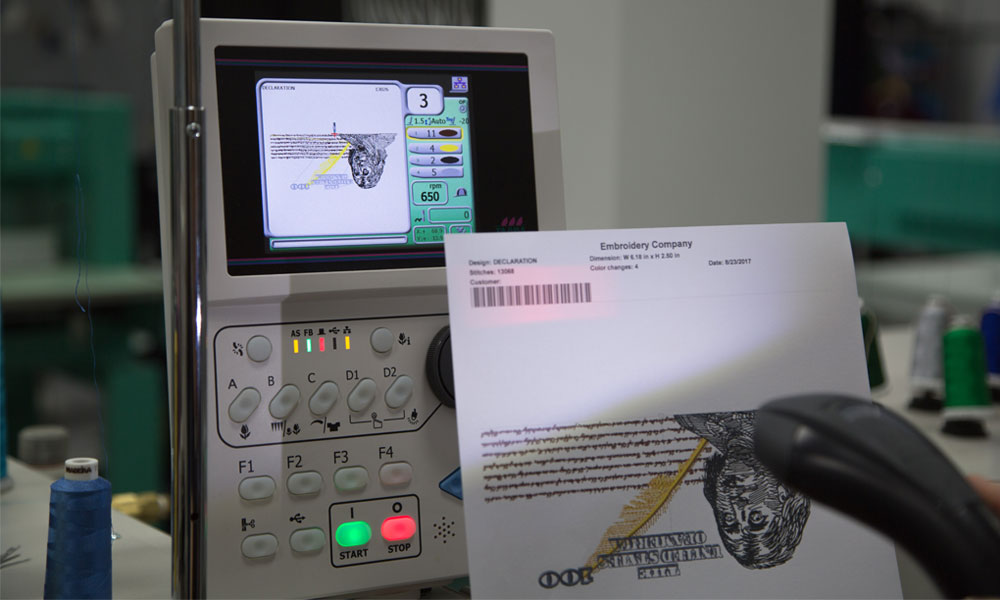

Keep in mind that there are a wide range of tasks that can be covered with the available software products. For example, work orders can be created that contain all of the parameters of a job and printed with a bar code. The machine operator scans the barcode at the machine and the design file downloads to the machine. Depending on the software and the embroidery machine, you can even load the thread sequence as part of the design file, rather than having to program it in manually. Another time saver.

To find the right production software for your shop, make a list of what you wish to accomplish, then compare it to the software products available. Keep in mind that there are some really good programs for very reasonable prices, but as your needs become more sophisticated, the price tag will go up. However, the important factor is not how much it costs, rather how much it will save you in the long run. Time is truly money with production, so every additional minute you can squeeze out of a machine is more cash in your pocket.

***

Jimmy Lamb is an award-winning author and international speaker with more than 25 years of experience in the apparel decoration business. Currently, he is the manager of communication at Sawgrass Technologies.