July 10, 2019

SOI 2019: Errors In The Promo Products Industry

As industry firms handle more business, distributors and suppliers are sharing the blame for order mistakes.

How often do promo orders arrive with errors? SOI data shows it happens 11% of the time, with mistakes ranging from inaccurate quantities to incorrect products to imprinting errors.

More SOI 2019: Back to Main Page

“There are so many variables when something goes wrong,” says Kenny Ved, VP of sales at supplier Goldstar (asi/73295). “It could be on the distributor side, it could be on the supplier side, it could be at the factory level or with the shipping carrier. We’re human; errors happen.”

The growth of the industry – approaching $25 billion annually – was cited by several firms as a big reason for the lack of quality control. More business is a good problem to have, but higher demand requires increased staff – a challenge in a tight labor market. “Our largest supplier partners are growing quickly and have many less-qualified operators to handle the growth,” says Jon Levine, president of The Image Group (asi/230069).

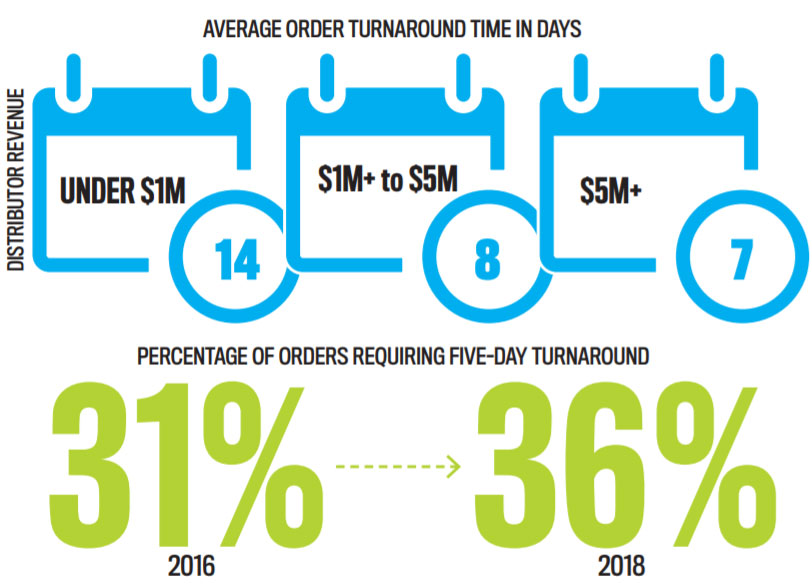

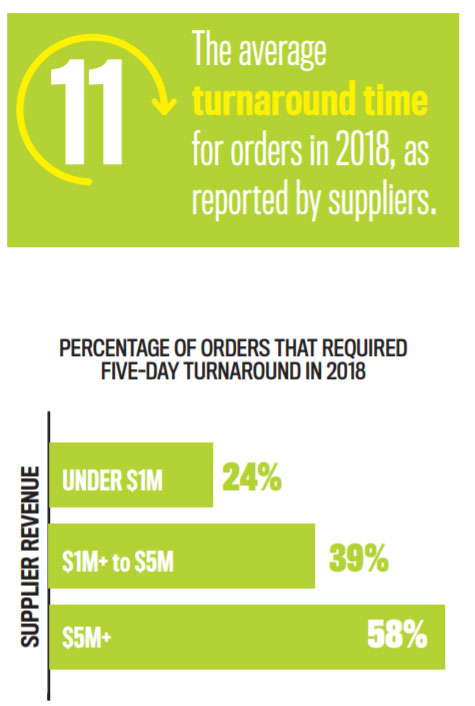

If finding people to fulfill orders is a major issue, the speed with which those orders come in – and go out – is right next to it. SOI data shows that 36% of orders require a turnaround of five days or less, and one casualty of meeting those deadlines is adequate time for review. “When you shorten the order cycle, you increase the opportunity for issues,” Levine says.

Staffing shortages and expedited orders may be obvious culprits when it comes to errors, but the most frequently cited reason is also the most surprising – because many distributors are pointing the finger at themselves.

Most distributors interviewed by Counselor accepted at least part of the blame for order errors, noting a few reasons for issues: the complex diversity of order software across suppliers; the wide range of variables among items and decorations; and the high expectations for quick delivery from clients. “You can only push so many issues off onto the supplier,” says Bret Bonnet, president of Top 40 distributor Quality Logo Products (asi/302967). “It’s our job to set customer expectations. It’s our job to make sure all information is translated in the right format for the supplier.”

Customers want their promo orders faster than ever and large suppliers especially are quickening process times. Among suppliers that annually generate more than $5 million in sales, about six in 10 orders had to be expedited in 2018.

Quite the Rush

It’s no secret that the internet has changed buyer expectations around shopping, customization and service, but no change has been as consequential – and costly – as expedited shipping. Promo buyers are coming to assume next-day and even same-day shipping as the norm.

“The expectation of fast turnaround, great quality, free shipping, and quick and easy returns have all become standard fare,” says Jeff Hall, president and CEO of Top 40 supplier iClick (asi/62124).

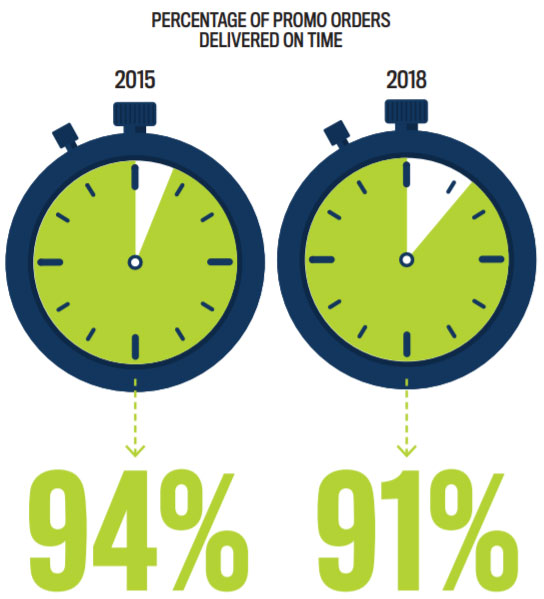

While more promo orders required a turnaround of five days or less in 2018 compared to prior years, a lower percentage arrived by the promised date – a big deal when competing against the streamlined processes of online firms. “The biggest challenges we have are bad purchase orders, incomplete information and bad artwork,” says Ved.

To combat avoidable errors such as these, more distributors are working to improve their order processing. “We’ve used a combination of investing in stronger internal systems, managing customer expectations, having better follow-up with vendors and pushing more spend to our reliable partners,” says Phil Koosed, president of Top 40 distributor BAMKO (asi/131431).

While smaller firms can’t afford quality-control departments, they can learn what goes into each order request so they can build those into their turnaround estimates. “Understand the time it takes for different decoration techniques,” says David Lever, director of sales for OTTO International (asi/75350). “For example, requesting a five-day turnaround on 5,000 pieces of a complex embroidery would be cut off prior to asking the supplier to make the mock up. If you know what goes into an order, you’ll know what can and can’t be accomplished.”

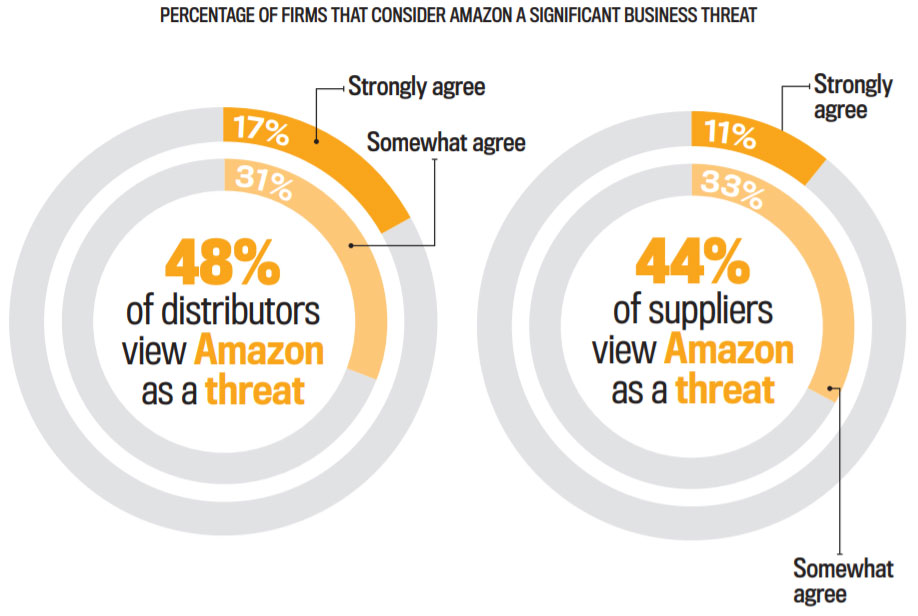

Distributors across all revenue classes view Amazon as a serious competitor in the promo space. Suppliers, though, are generally less concerned, in part because they can more easily leverage Amazon to sell their products.

The Amazon Effect

When you talk about rush delivery and intense client demands, you can’t avoid the trillion-dollar elephant in the room: Amazon. About 48% of distributors and 44% of suppliers agree that Amazon poses a threat to their business, and promo leaders are rushing to meet the high expectations set by the Seattle-based giant. Which begs the question: should they?

“There’s no question it’s incredibly expensive, time-consuming and complex to develop all of the systems, capacity and teamwork needed to produce customized products that ship next-day,” says Hall. “One of the reasons we’re starting to see so much consolidation in our industry is because of the resources it takes to offer these services.”

Opinions are divided as to whether competing with Amazon is a must of doing modern business or a recipe for failure. There are clearly industry execs, though, who believe expedited orders have worsened the order cycle dynamic. “The industry has put unnecessary pressure on itself by offering 24-hour shipping at no charge,” says Trevor Gnesin, owner of Top 40 supplier Logomark (asi/67866). “This has allowed the end-user to leave everything to the last minute.”

Memo Kahan, president of Top 40 distributor PromoShop (asi/300446), feels the message to promo buyers needs to be reconsidered. “If we slowed everything down a little and gave factories enough time to produce, it would diminish the issues,” he says. “The customer is pissed off for sure. But it’s up to us to retrain them that they shouldn’t be ordering things today for tomorrow.”

There are some leaders, though, who relish a chance to stand out with speed. “The answer isn’t to run away from higher expectations,” says Koosed. “The answer is making investments in technology that allow us to exceed those expectations, no matter how high.”

According to distributors, suppliers are increasingly failing to provide products by the promised date. The trend is especially troubling as online competitors are delivering items sooner than ever.