April 16, 2019

Why Screen Printers Should Add DTG to Their Shops

Now may be the perfect time to nudge your screen-printing shop toward digital decoration by offering an excellent complementary service: direct-to-garment (DTG) printing. This decorating method lets you print custom short runs (even on demand), creating a lucrative income stream almost immediately. Here are five reasons to look into DTG this quarter.

1. The money’s already there. The cost of DTG printing in comparison to the price you can charge creates a lucrative opportunity, with amazing profit margin possibilities. Plus, the cost for entry into DTG is a lot lower than other inkjet technologies. You’ll recoup that investment — within a year — if you print 60 shirts a week at a $10 profit per shirt.

2. On demand is in demand. Since DTG is a digital technology, you can print samples and short runs — even on demand — much easier and more quickly than you can with screen printing. The setup effort can be as easy as obtaining digital artwork from your clients, and you can print full-spectrum color garments with the press of a button. In addition, for quick-turn orders, you can charge a rush fee — after all, you’re providing custom apparel or accessories on a need-it-now basis. Paired with your more labor- and time-intensive screen-printing setup efforts, this is an excellent way to cover all your customers’ printing bases. DTG printing expands beyond T-shirts: Some manufacturers have the capability to print on shoes, bags, coasters, hats and more.

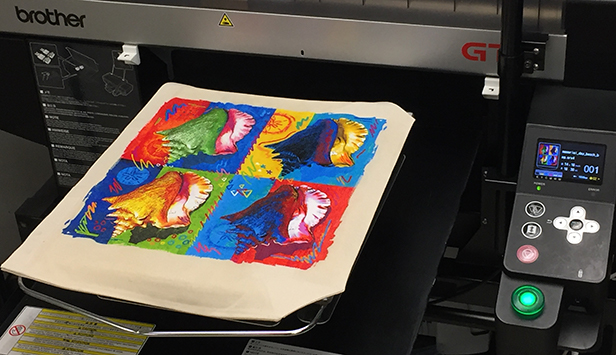

3. Offer high-quality, small-volume printing. Even on a single-shirt order, the print quality’s there with a DTG printer: You’ll be able to achieve photorealistic images in exacting detail, with gradients and color transitions. You can continue to fulfill much larger orders with your screen-printing setup, or opt to tackle your larger orders with DTG as well.

4. Love on Mother Earth. While some screen-printing inks contain PVC, phthalates or other chemicals, several DTG printer manufacturers are OEKO-TEX 100 certified, ensuring that their water-based inks, cleaning solutions and other DTG processes are environmentally safe. This is a great benefit to tout to customers, especially if you’re committed to being a sustainable shop.

5. DTG is a simple process. That means you can easily teach your operators how to handle an order from end to end, and not worry about a long learning curve. DTG’s basic steps are: pretreat and cure the garment; import the art into your graphics program and make any adjustments; put the garment on the platen and print; and then use a heat press or conveyor dryer to cure the garment.

The best way to decide whether DTG is the right add-on for your shop is to check out the technology and the printed pieces for yourself, either at an industry trade show, or even in another shop that’s currently offering the service. Most likely, you’ll wonder why you didn’t add it sooner — and your clients will thank you for giving them an additional printing option.

***

Ed Levy has more than 25 years of apparel-decorating experience. The director of software technologies for Hirsch Solutions, Levy frequently speaks at trade shows and contributes to industry magazines.