March 08, 2019

The Secrets of Sampling in the Promo Industry

There’s a surefire way to close a deal, and it’s not a catalog, website or virtual proof. Industry experts give away (for free!) their knowledge on the best sales tool you’re not using.

Everyone loves the word “free.” You can find it everywhere you turn, from free shipping and free setup to fat-free foods and pain-free remedies. And free stuff, of course, which is the name of the game with promotional items. You get to be the bearer of free T-shirts, hats, drinkware and wireless earbuds, and every sales call ends with the same request: “Can you send a free sample?”

Don't Miss: When to Request a Sample

Of course, all those free products are anything but. Before an item lands on your prospective buyer’s desk, it goes through a long chain of research, development, production, testing, shipping and more. Each step in that process has a cost, which means every free product has an associated value. And that makes each sample a valuable – and powerful – sales tool.

Samples have long been a part of the decorated-apparel industry, but they’re more than a gift for your customer. When used correctly, dedicated sampling can make you stand out from the competition, lead to add-on sales, solidify your role as a marketing consultant and potentially save you from a career-ending mistake. Before you drop that next “free” product in the mail, make sure you understand the best ways to use samples to grow your business.

The Purpose of Samples

Picture this: You’re walking through the grocery store when you come across a table where an apron-clad employee, working over a hot plate, hands you a 1-inch-by-1-inch square of lasagna in a plastic cup. Did he do this because he thought you were hungry? To thank you for shopping at Food-o-rama?

The reason you received some free cheesy pasta is in hopes that you’ll leave the store with a box or three of lasagna in your shopping cart. Free samples exist to convince the recipient a purchase is worthwhile. This is true in the supermarket aisle and it’s true in your prospect’s office.

“Nothing sells the product like the product,” says Chris Guard, marketing manager for HanesBrands, parent company of Hanes Branded Printwear (asi/59528). If a picture is worth a thousand words, then an in-hand sample is worth a thousand .jpgs. “Nothing you say or write about thread count and fabric quality,” Guard says, “resonates like touch and feel.”

Promotional products and apparel are a physical marketing medium, one that can affect all the senses in a way a billboard or banner ad can’t. That gives you a sales tool with which other marketers can’t compete. When a prospect is on the fence, a hands-on experience can be the deciding factor in a sale. “There’s no substitute for a client seeing an actual product sample,” says Mitch Silver, vice president of Chicago-based Printable Promotions (asi/299458). “We think of free samples as part of our marketing budget. It’s hard to expect someone to make a large buying decision without having an actual sample in their hands.”

“Nothing you say or write about thread count and fabric quality resonates like touch and feel.” — Chris Guard, HanesBrands

Samples also serve another crucial purpose: ensuring the quality of the finished product. A spec sample lets you pump the breaks before a 10,000-print run ends up costing you thousands due to something going wrong. And things can go wrong when you’re dealing with customization. Maybe there’s a mistake in the artwork. Maybe the ink absorbed in an unpredictable way. Maybe the customer ignored your repeated warnings that putting a matte black logo on a matte black product might make it hard to read. Maybe the client just changed her mind. Maybe the product isn’t what she envisioned.

Tony Poston, founder and president of distributor College Hill Custom Threads (asi/164578) in Seattle, recalls a previous order of about 5,000 keychain carabiner flashlights. “For some reason, my sales rep was certain the customer would love the product, but I made him get a pre-production sample because we’d never actually seen or felt the product,” he says. “When we got it in, he delivered it to the customer and she did not like it one bit. Luckily, we had another product in mind that was at an even higher price point and better margin and we had a sample to show her. She loved it and the order ended up being great for everyone.”

Dealing With Decoration

Selling apparel comes with its own set of complications. Inks react differently to fabric than they do to plastic and other substrates, and you’re often dealing with more complex decorations, like embroidery. That makes custom samples and sewouts even more imperative for decorators, in addition to providing expertise to ease the process for clients and distributors.

The first thing to consider with apparel decoration is that there are a lot of options, and some lend themselves more easily to sampling than others. Asking your decorator for a digital print is very different from asking for embossed leather. Some styles will have more lead time, different artwork requirements and even additional costs.

When it comes to something like embroidery, one of the more complicated processes, requesting a proof is generally a good idea. “However, the client does need to realize there can be a cost to embroidering a sample,” says Rob Dubow, CEO of Dubow Textile (asi/700107), a contract apparel decorator based in St. Cloud, MN. “They should either get the actual sewout from the digitizer or understand they’ll be billed for the cost by the embroidery company.”

Suppliers are willing to provide sample kits and pre-made samples, such as this kit from Hanes Branded Printwear (asi/59528).

As for screen printing, spec samples can be tricky. “The costs of setup are high, so proofs aren’t as important, but should be offered at a cost,” says Dubow. Some decorators will use direct-to-garment printing as a tool to sample potential screen print orders (due to the ability to cost-effectively print one-offs), but it must be made clear to buyers that the colors and look of the design will vary between the two techniques.

Producing a sample for a DTG order is also recommended. “Not all direct-to-garment printers are made the same, and not all shirts are made the same,” says Nick Worthington, marketing and sales director for Stitch Designers (asi/741145) in Louisville, KY. “We see that most 100% cotton shirts work well for direct-to-garment printing, but there are some that don’t. These shirts could be made in different countries or with different dyeing processes, which could cause different end results when printing. We want to eliminate any possibility of a bad print, so a lot of times we will do a pre-production sample for final approval before running the entire order.”

Which brings up another concern when working with any decoration technique: the item’s fabric. While an emailed proof is likely sufficient for something as straightforward as a digital print on a 100% cotton T-shirt, things like synthetic materials, fabric blends and irregular decoration locations are all good candidates for spec samples, says Dubow. In other words, if you’re uncertain how the decoration will look, ask.

38%

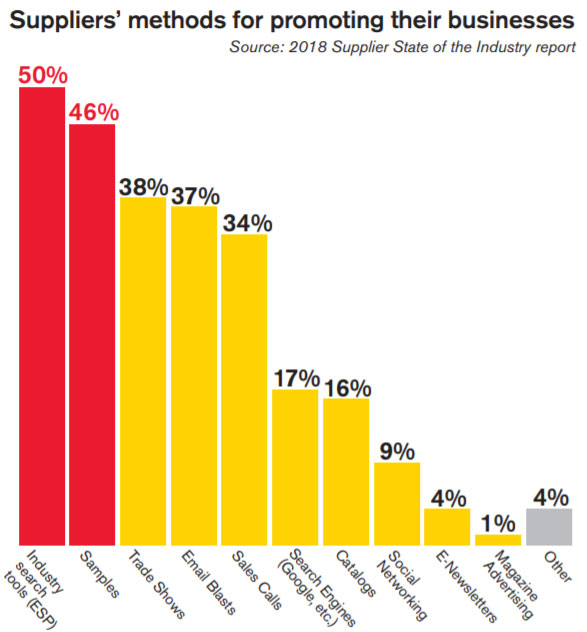

Percentage of suppliers who planned to increase their use of samples in 2018.— Source: 2018 Supplier State of the Industry report

Worthington advises extra caution with larger and more complicated products such as luggage and bags. These products may use harder materials, like leather or thick canvas, which are more difficult to embellish than cotton or polyester. They also tend to be more angular, include additional complications like zippers and straps, and offer fewer flat surfaces to decorate. Even a simple design can be hard to reproduce on a backpack with multiple pockets and openings, so a physical proof is vital to ensure the quality of the promotion.

“If you can imagine trying to embroider a small logo on the ball pocket of a golf bag, that’s difficult,” Worthington says. “There’s some creativity needed to suspend the bag to take all the weight off the embroidery machine and line up the correct area for the decoration. When it comes to sampling, not only do you need to look at the complexity of the logo, but also the challenges of handling and hooping the product itself. It takes experience to know how to successfully decorate on the more challenging items.”

Creating a Sampling Program

The first sale is always the hardest. You need to get your foot in the door, demonstrate your value as a marketing consultant, show that you can provide the perfect product and then deliver everything on budget and on time. It’s that first step – making the initial contact and creating a relationship – that often proves the greatest challenge. You need every advantage you can get. For many, that means creating a sampling program to showcase everything they can offer first-time buyers.

When developing a sampling program for your company, a good place to start is with your closest supplier partners. Many of them have programs with pre-made sample kits that feature all of their best-selling products, while others may be willing to provide specific items in advance of a sales meeting. “Sales reps talk about what they know and sell what they talk about,” Guard says. Hanes can offer blank apparel as well as items decorated specifically for your prospect’s market. “We want to make it as easy as possible for sales reps to talk about, show and even wear our products,” Guard adds.

Nearly half of suppliers give out samples, ranking it ahead of trade shows, email blasts and sales calls.

To truly wow a prospect or client, bring a custom-made or printed sample. “All presentations can and should include samples, preferably pre-production samples,” says Scott Opper, CEO of Clothpromotions Plus (asi/45513) in Boca Raton, FL. “If time and budget limit this and you can’t produce for every presentation, identify valued relationships, large accounts and ongoing accounts. In other words, make it part of the relationship, not part of the sale.”

It definitely makes sense for bigger customers, says Taek Sung, vice president of sales and marketing for iClick (asi/62124). “There are times when you deal with larger clients with big projects, and you have to put a pre-production or spec sample in front of them before they’ll make a decision,” says Sung, who was also formerly with Counselor Top 40 distributor BDA (asi/137616) and understands both sides of the business. National corporations with deep pockets have high expectations – if you ask them to pick items out of a catalog, they’ll ask you to see yourself out. Impressing prospects like this may require getting samples with the client’s logo on a variety of products before you even have your first meeting, but the payoff for landing one of these accounts can far outweigh the extra cost and effort.

“There’s an initial upfront cost of doing samples, but that price could prove to be well worth it in the end.” — Nick Worthington, Stitch Designers

Presentation also matters when developing your sample program. You’re not going to land many sales with pens and polos hanging from inside your trench coat like knockoff Tiffany jewelry. If you specialize in a select handful of products, consider investing in a briefcase with die-cut slots and pockets for each item you sell, and replenish it between each sales call. Apparel can merit a rolling garment rack outfitted with a curated selection of high-quality samples. (A showroom at your shop can have a wider selection of available garment styles.)

Another effective tactic, particularly when fishing for new business, is to develop a mailable box packed with the most popular products from each of your best partners. Many suppliers are happy to provide you with self-promotion items once you’ve proven your worth as a business partner, giving you a steady stream of samples to mail to your top prospects. If you go that route, consider creating mail-ready cardboard boxes branded with your company logo and contact info to really sell your worth as a marketing professional.

One thing to avoid, however, is treating samples like your own personal business card. Good samples have real costs behind them. If you request one for every prospect you meet – including those you know will never turn into clients – you devalue the products and can damage your relationship with suppliers. Instead, handle samples like you would any other purchase from a customer. “Treat any sample request as an actual order so there’s a complete history of what’s being done in case an actual order is sent,” Dubow suggests. “Samples take time, so asking for a creative solution to be done as a rush is unreasonable most of the time.”

Finally, before placing any sample orders, realize that sample requests require more than just putting an item in a box and mailing it. Any given request could involve the marketing, art, production, sales, fulfillment and management departments at a supplier. A lot of work goes into each “free” sample, which means sometimes there may be a cost to you. Blanks and randomly decorated items are less likely to merit a charge, while spec and client-decorated items most certainly will. And the pricing will certainly vary among suppliers, though EQP or EQP minus 30% are some common options.

“There are processes behind the scenes where we might do two or three sew-outs before we actually run the physical sample,” Worthington says. “It can take a little bit longer to make sure we have met our and our customer’s quality standards before we decorate on the piece itself. There’s an initial up-front cost of doing samples and they come with a price because of how many people touch it. That small cost could prove to be well worth it in the end.”

Kyle A. Richardson is a contributing writer for Wearables.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.