October 01, 2018

Using Automation to Jumpstart Your Decorated Apparel Business

The right equipment and software – paired with thoughtful processes – can increase productivity and profits.

he term automation often conjures up stark images of job-stealing robots – well-oiled mechanical arms methodically picking and packing, sorting and stacking on sterile factory floors.

he term automation often conjures up stark images of job-stealing robots – well-oiled mechanical arms methodically picking and packing, sorting and stacking on sterile factory floors.

Then there are the chilling statistics: By 2030, according to a report by management consulting firm McKinsey Global Institute, as many as 73 million U.S. jobs could be replaced by automation.

Wearables: The Innovation Issue

It’s a scary thought, but automation doesn’t have to be a dirty word. In fact, automating your decorated-apparel shop – through equipment, software and streamlined processes – can be a job saver and perhaps even a job creator.

Consider the case of Campus Ink in Champaign, IL. When 20-something Steven Farag became a co-owner of the decades-old mom-and-pop shop, he was determined to usher it into the 21st century, but didn’t have the funds to buy shiny, new automatic presses or fancy computer-to-screen systems right away. “I wasn’t able to automate my equipment, so I automated everything else I possibly could,” he says.

Podcast

Steven Farag, co-owner of Campus Ink, explains why automation is the key to his shop’s growth.

That involved creating a workflow diagram of every step in a particular job, then finding inexpensive software solutions to take over wherever possible, from the sales process to artwork creation to customer follow-up and beyond. For example, Campus Ink uses business management software that sends emails or even a text to the customer for artwork approval. If no approval is sent within a set time, the software will automatically follow up. The same goes for when there’s a problem with the artwork. Instead of having to track down the salesperson or customer to get answers, the graphic artist can simply flag the issue, which triggers an email to the customer seeking a resolution.

Farag uses email tracking and scheduling apps, which can do things like send reminders if an initial email isn’t answered within a certain timeframe. Another app called JotForm lets him easily create online forms, which can be simultaneously launched on email and online marketing platforms thanks to Zapier, an automating tool that connects apps and performs simple actions. He hired a virtual assistant to work remotely a few hours a week to take artwork proofs from Dropbox and turn them into Instagram posts, tagging the customer.

All told, Campus Ink spends around $10,000 a year on automating apps and software. “It still doesn’t equate to one full-time employee,” Farag says. But in the four years Farag has been with Campus Ink, refining its processes and automating wherever it made sense, the business has seen 300% revenue growth. They’ve hired dozens of “student ambassadors” – college students who work on commission, selling decorated apparel to their classmates. And they recently moved into a 12,000-square-foot facility stocked with much of that fancy decorating equipment Farag coveted when he first joined the company. “We’re in a spot where we’re ready to take off,” he says.

The key, when it comes to automation, is not so much to eliminate jobs as it is to eliminate tedium and jumpstart productivity. “We have people working and doing the tasks they’re supposed to be doing,” Farag says, “and not wasting time on menial, repetitive tasks.”

n the upcoming Wearables State of the Industry report, 73% of decorated apparel companies agreed that automation of apparel decoration techniques will be a significant trend in the next three to five years. So decorators see the potential for automation in their shops with everything from order processing to automatic decoration equipment. But seeing the future and actually implementing it are two different things. Take something simple like order entry. “We see a lot of double order entry and manual order entry,” says JP Hunt, partner and co-founder of software firm InkSoft, which offers an e-commerce and online design platform, as well as other business tools, to decorators. “We hear horror stories of shops that have a staff member whose entire job is to record orders in QuickBooks.” Not only is this a waste of valuable employee time, it’s also a breeding ground for error.

n the upcoming Wearables State of the Industry report, 73% of decorated apparel companies agreed that automation of apparel decoration techniques will be a significant trend in the next three to five years. So decorators see the potential for automation in their shops with everything from order processing to automatic decoration equipment. But seeing the future and actually implementing it are two different things. Take something simple like order entry. “We see a lot of double order entry and manual order entry,” says JP Hunt, partner and co-founder of software firm InkSoft, which offers an e-commerce and online design platform, as well as other business tools, to decorators. “We hear horror stories of shops that have a staff member whose entire job is to record orders in QuickBooks.” Not only is this a waste of valuable employee time, it’s also a breeding ground for error.

Try sitting down and typing out 100 unique names without making a single mistake, challenges Brian Goldberg, president of Pulse Microsystems, which develops software for product personalization, apparel decoration creation and automation. “Statistically, we see time and time again a 5% error rate,” he says. “That doesn’t sound very high, but one out of 20 will be wrong in the worst possible way. You’re spelling someone’s name wrong. The implication is not just the cost of a damaged article, it’s also the loss of a customer and all of that customer’s friends.”

Ideally, customer data should be entered into a shop’s system once – preferably by the customers themselves, perhaps using an intuitive online order form. “We’re strong advocates of trying to eliminate junctions where mistakes can be entered,” Hunt says.

Once the order is in the system, shop management software will often ensure you have the right items in your warehouse or automatically send the purchase order to the proper suppliers. “Nobody on your side or on the vendor’s side in sales re-enters the order,” says Erich Campbell, partner relationship manager for DecoNetwork, a software company that helps decorators manage their business and build websites and online designers.

Some software is even able to send design parameters directly to decorating equipment, which helps eliminate setup errors. It also speeds up production considerably. “In a non-automated factory, an operator could handle at most two embroidery machines,” Goldberg says, noting that they would be bouncing back and forth setting up and monitoring each. “In an automated factory, the operators are managing five to 10 machines. Those machines aren’t sitting there waiting for an operator. The design comes immediately into the machine, and everything is set up. The machine isn’t down as long either. Basically, it’s a dramatically more productive way to work.”

Another benefit of automation is consistency, particularly for reorders. With programs like DecoNetwork, for example, a decorator can easily queue up artwork the customer used in the past. “You don’t have to go to an art repository or contact the artist to prepare it again,” Campbell says. “The file itself is production-ready, including any customization that was done.”

Shop owners and production managers can also use automation software to define “business rules” that set the parameters for particular products, such as what underlay or pull comp to use for embroidery. That way, Goldberg says, they can scale their business without always having to rely on the skill of the machine operator to ensure decoration quality.

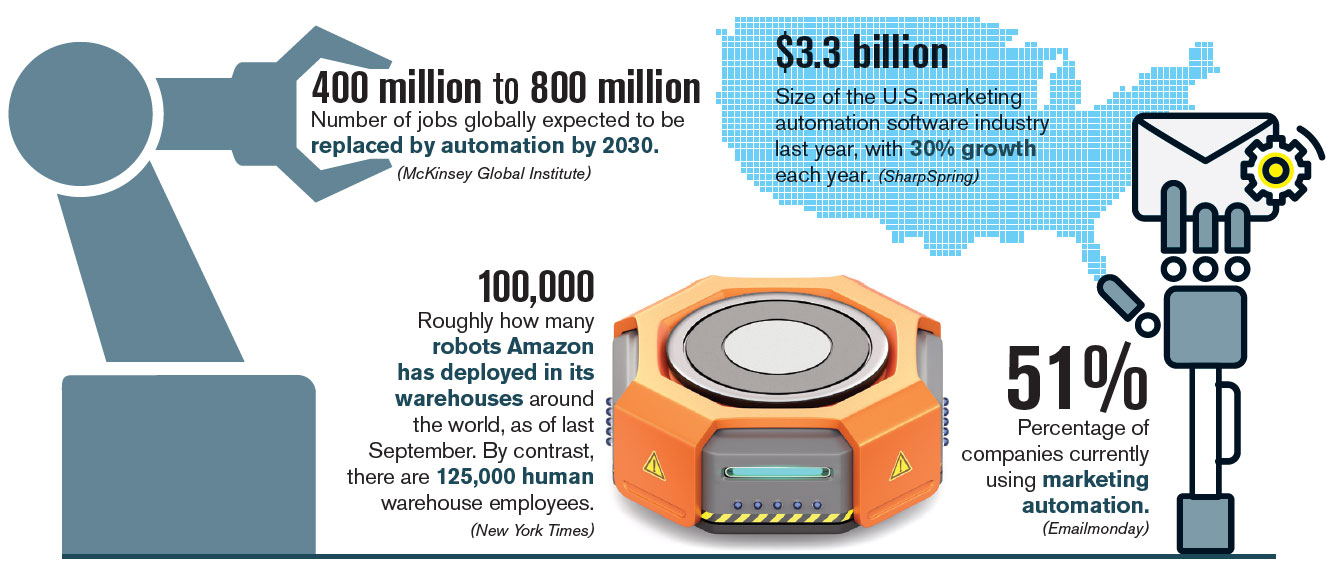

Automation By the Numbers

Automation means different things to different people, but whether you’re talking about actual robots or just software solutions, the fact remains that automation is a dominating force in the business world. And its influence is only expected to grow. Click here for a larger image of the above graphic.

or small shops out there still doing everything by hand – filling out paper order forms and pulling their own squeegees – the prospect of automation can seem daunting. But think about how much the decorated-apparel industry has changed in the last few decades. “We’re kind of like frogs in water that’s starting to boil,” Campbell says. “We got used to the amount of automation we have now and don’t remember how manual things used to be. … I know people one generation back from me who were hand-cutting Rubylith to make screens.”

or small shops out there still doing everything by hand – filling out paper order forms and pulling their own squeegees – the prospect of automation can seem daunting. But think about how much the decorated-apparel industry has changed in the last few decades. “We’re kind of like frogs in water that’s starting to boil,” Campbell says. “We got used to the amount of automation we have now and don’t remember how manual things used to be. … I know people one generation back from me who were hand-cutting Rubylith to make screens.”

It shouldn’t be surprising or scary, then, that the trend continues. Shop owners who want to remain competitive need to welcome progress. “Let’s not be the last guy selling spats,” Campbell says.

“We have people working and doing the tasks they’re supposed to be doing, and not wasting time on menial, repetitive tasks.”Steven Farag, Campus Ink

Even with all of the shop automation tools out there, experts say the decorated-apparel realm still lags behind other sectors. “If you look outside the industry to something like Amazon that has robots driving goods around the warehouse, bringing them to fulfilment and shipping them out, print shops are 15 years behind that,” says Bruce Ackerman, founder and CEO of shop management software Printavo. “There’s so much more we can do.”

Ackerman says his team is striving to help transform decorated-apparel businesses into “modern warehouses where everything is interconnected and people are able to make better decisions.”

Though increased automation is inevitable, the shop of the future will still have space for the human touch. Areas like sales, marketing and customer service benefit from having real people at the helm, rather than automated systems. And the design side of decoration will likely still be human-driven. “There may be space for all of us to turn into consultants and do the creative work, but not the production work,” Campbell speculates.

Even today, not every task can be easily replaced by a robot or phased out with automation software. Carmaker Tesla, for example, had to pull back on its attempt to automate everything on the production floor, with owner Elon Musk admitting in an April tweet that “excessive automation was a mistake” and “humans are underrated.” Programming a robot to weave the wiring loom of a car into the frame is much more difficult than just having a person handle it on the assembly line. In the same way, the floppy nature of apparel means shops will likely need workers to load and unload garments onto machines for years to come.

“Sometimes,” Hunt says, “it’s stupid to take a simple human task and try to build a robot around it.”

THERESA HEGEL is the executive editor of Wearables. Contact: thegel@asicentral.com; follow her on Twitter at @theresahegel.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.