We love the promo industry. But we know it can be better.

How? In this series of stories, ASI Media explores five big ideas that can transform the world of promo. These aren’t quick fixes or simple changes. But with enough consideration, ambition and coordination, we think they’re all possible. And our beloved industry – and the people who live and breathe it – will be better off for it.

Ordering online these days is usually so quick and easy that by the time you’ve second-guessed the necessity of a purchase, it’s already at the front door.

That’s not the case with promo. Even as fulfillment times have declined dramatically in recent decades, the promotional products order process can still take weeks (if not months) from first conversation to final delivery. Sure, part of that is valuable time taken to brainstorm with a client and agree on solutions. But it’s also the many wasted hours spent going back and forth – making changes, filling in missing information, finalizing the order and fruitlessly tracking it.

And that’s the problem. In this age of lightning-quick retail order placement and delivery (thanks Bezos), the branded merchandise industry continues to lag behind. Placing and tracking a promo order is still woefully slow, clunky and convoluted.

5 Ideas to Improve Promo

1. How to Change Our ‘Brandfill’ Image Problem

2. Can the Promo Industry Go Plastic Free?

3. The Path to Getting Out of China

4. Use These Ideas From the World’s Biggest Companies to Improve Diversity

5. The Blueprint to Improving Promo’s Convoluted Order Process

Distributors say, ideally, they’d like to spend more time prospecting, brainstorming creative projects and building relationships with their clients. Instead, they spend much of their days, nights and even weekends trying to find basic information at suppliers’ websites to submit POs, approving proofs and tracking down shipments to give clients updates on their orders. Meanwhile, say suppliers, a good portion of POs they receive are incomplete or inaccurate, and each distributor operates a little differently, which makes system integration a challenge.

Sandy Gonzalez, CEO of MadeToOrder (asi/259540) and a member of Counselor’s Power 50 list of the most influential people in the industry, recently had to make several phone calls to a supplier to confirm information before she could submit a PO. Inventory levels weren’t on the website, and the current production timeline wasn’t clear.

“Making all those calls was the biggest waste of time,” says Gonzalez. “When it comes to holdups, it’s 100% a lack of communication on both sides. Figuring out how to place the order takes 10 clicks.”

“When it comes to holdups, it’s 100% a lack of communication on both sides.”Sandy Gonzalez, MadeToOrder

Once the PO is submitted and acknowledged, the work isn’t done. Gonzalez says she and her team normally have to reach out for tracking and then monitor the order’s transit progress themselves. When suppliers rely on UPS and FedEx for tracking, it often goes to the wrong person at MadeToOrder, and/or it doesn’t reference the client or products being shipped, so the team spends time straightening it out. “We have to staff for this,” says Gonzalez.

Gonzalez’s experience neatly sums up a messy reality. The promo products industry suffers from a lack of standardization for placing orders, and then little to no communication to see the order through to arrival at its final destination. The problems are legion: lack of money, willingness and manpower to invest in new technology; a dearth of trained and experienced staff (especially these past two years); vastly different operating procedures across the industry; and slow adoption by sales reps. Many of these problems aren’t new, but the industry-wide fallout from the COVID pandemic – order delays, supply chain disruption and worker turnover – has greatly exacerbated the situation.

The issue hasn’t gone unrecognized, and there is critical work being done by technology-minded suppliers, distributors and industry organizations to address the issue. However, it’s a slow process. Because while there is agreement about the need for automation and digital integration in promo, it’s another matter to agree how to do it – and then unite thousands of distributors and suppliers under a single platform or universally accepted standard.

“The industry needs to define and structure all interactions among the three parties: suppliers, distributors and end-buyers,” says Phil Gergen, senior vice president of technology at Top 40 supplier Koozie Group (asi/40480), and a board member for PromoStandards, an industry organization of volunteers committed to streamlining orders with standard operating procedures. “When we can increase the speed and accuracy of communication, we can shorten the order process,” he adds.

If that were to occur, the added worry is that end-buyers may come to view the promo ordering experience as one of product-peddling, akin currently to an impersonal digital retail experience. In an automated environment, can promo retain all of its complexity, service mentality, marketing expertise and personal connection? Can it have the best of both worlds?

Hiccups From the Beginning

According to suppliers and distributors, the friction begins out the gate. Before a PO can be processed, distributors need all the relevant information to fill it out in a timely manner, but it comes in all different forms from suppliers. “All the details need to be translated for the three parties to get the order produced correctly and quickly,” says Gergen. “Speed is important, but across the industry, the amount of information needed to successfully complete an order is inconsistent across products, options and decoration capabilities.”

Jon Norris, COO of Top 40 supplier Starline (asi/89320; Canada, 89213) and a member of Counselor’s Power 50 list, says the most significant holdups by far are caused by incomplete POs, a problem that grew over the past few years when distributors would submit unfinished orders just to secure fast-disappearing inventory.

“Fewer than half of the POs we receive require no back-and-forth,” says Norris, who along with Gergen serves on the board of PromoStandards. “We see incorrect product codes, incorrect decoration and no placement stipulated. One of PromoStandards’ objectives is to eliminate the freeform information fields on POs, like the boxes that just say ‘Other,’ or ‘Notes.’ For the past 20 years, distributors have just written out what they needed. Now, we want to see specific fields that need to be filled in, so they can be integrated with a supplier’s order system.”

The Latest Problem

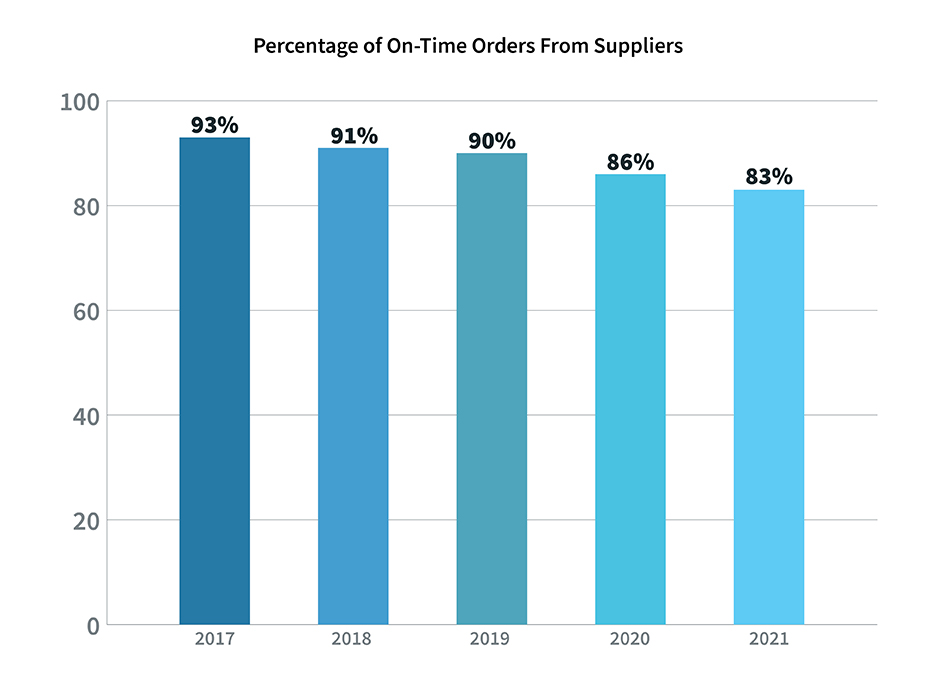

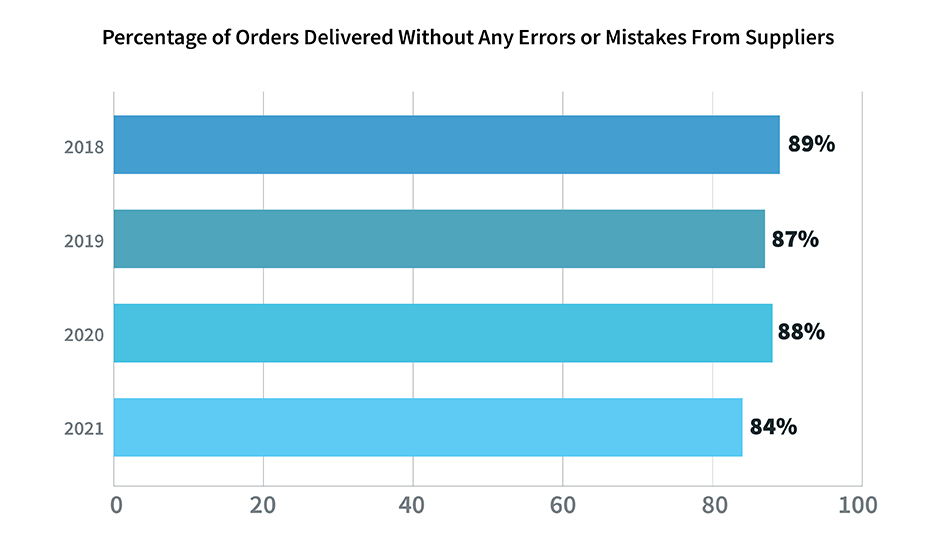

A streamlined process is even more important now as on-time orders continue to decline and errors increase.

(Counselor 2022 State of the Industry Report)

Filling out POs completely is a matter of being detail-oriented, but it’s also complicated by one of the industry’s greatest strengths – the sheer volume and variety of products and suppliers available to distributors. “There are so many different companies, SKUs and decoration processes that it’s hard to keep track,” says Daniel Siegel, director at Industrial Contacts (asi/231220). Plus, adds Gonzalez, suppliers often don’t have standardized names for decoration processes and rush order services, requiring the distributor to educate themselves on how a given supplier operates and then relaying that to the end-buyer. “When a client asks about a product that’s from a vendor we don’t normally work with,” she says, “I cringe.”

“Once the industry has agreed upon how to translate data, automation can increase at an escalated rate.” Phil Gergen, Koozie Group

Yet another complex area of the order process is pricing, says Tim Andrews, president and CEO of ASI. A single order can include the product price, run charges, set-up charges, different prices for different apparel sizes, blanks pricing for items slated to be decorated, and decoration charges, he says.

“And don’t forget packing and shipping costs, and under- and over-counts,” Andrews adds. “You almost need a degree from Princeton to figure it out, and much of it doesn’t reflect how modern business works. Suppliers that simplify things could provide major disruption by pricing their products all in – here’s the price, with one-color or full-color decoration, and shipping anywhere in the U.S.”

How the information is received and orders are processed often differs from company to company, and how distributor sales reps are trained to submit orders can vary, “but still, we have to make sure no PO information is missing,” Siegel adds.

Even if automation in promotional products would bring added efficiency, human eyes are still required to finalize an order, in case an imprint just won’t look right, for example. That’s something a machine wouldn’t pick up on.

“We also have to consider special services, like dropshipping, which has to be quoted effectively by a knowledgeable team,” says Siegel. “There’s time lost in processing, even before production begins.”

There’s still a lot of manual labor required on both sides, agrees Michelle Chen, owner and sales director at Fossa Apparel (asi/55141). Ordering garments in particular is labor-intensive, with its many different aspects, from style, color and size, to decoration and placement. All of that has to be decided on and agreed upon by the distributor and end-buyer, which takes proofs and sampling.

“Suppliers and distributors have their own internal systems for order management and enterprise resource planning,” she says. “That’s why order processing is still very manual – it often requires staff at the supplier to take a PO and enter it into their system.”

Meanwhile, staff shortages continue to plague the industry across the board. Miriah Cassidy, vice president of operations for Top 40 distributor American Solutions for Business (ASB, asi/120075), says both suppliers and distributors have been challenged to find, train and retain people who are dedicated to solving problems in a complex industry. “The workforce now has more people currently in training than ever before,” she says, “but this leads to an uptick in delayed responses and errors.”

Part of that training, particularly for distributors, must include what a PO requires and how to submit them for each vendor. Avoid using Excel or emails, which can be difficult for suppliers to process, says Bryan Goltzman, co-owner of Liquid Screen Design (asi/254663).

“It’s the Wild West,” he says. “Distributors need to take a look in the mirror and invest in a platform like ESP. Submitting POs through a platform shows they’re legitimate.”

However, some sales reps still have a hard time submitting an order totally online – they’re used to calling their rep, says Gonzalez. That makes universal adoption of even the most advanced technology a challenge.

“They pick up the phone first and don’t even look at the supplier’s website,” she says. “The industry tends to have a lot of chatty phone people who want to ‘get the favor.’ But we’re in the era when it’s more difficult for suppliers to answer because workloads have doubled and tripled.”

It’s also hard for new distributor sales reps in training who end up picking up the phone multiple times for clarification. “It can take them hours to submit a PO,” says Gonzalez, Counselor’s 2021 Woman of Distinction, “and during COVID it got worse. It took days or they never heard back from the supplier.”

Once the supplier receives the order, there’s lots of back-and-forth with proofing, often through email. Says Siegel, “That’s another area of friction, all the proofs and revisions, which leads to holdups.”

Norris favors more ability for distributors to change their order as needed within the supplier’s system after it’s been submitted. That way, if a certain color is no longer available, for example, they can quickly make a change without having to call or email.

“We’ll ask for black tumblers, and they’ll say they don’t have any,” says Goltzman. “But they have white. So why don’t they say, ‘Would white work instead’? Why do I have to ask that? If it was automated, we could sign in, see what they have and do what we need to do.”

Industry platforms like ESP have features that address those concerns. Andrews underscores the idea that technology can greatly help with the complexity of handling orders.

“We’re a complicated industry, since every order is 100% custom,” says Andrews. “It isn’t like buying toothpaste or diapers at Target.com. It’s selecting 1,000 T-shirts, in nine or 19 sizes, with artwork in various locations and several decoration methods. So we need to standardize and simplify where we can. At ASI, we’ve been providing a standard PO for a decade, designed by suppliers and distributors, and plan to update and embed it even more prominently in ESP at the turn of the year. More use of ESP’s capabilities for ordering and tracking would eliminate thousands of calls and emails across the industry.”

Waiting for Answers

In retail e-commerce, most customers can expect a series of emails keeping them apprised of their order status, without ever having to talk to a live person. Not so in promo. While some suppliers may have automated updates, others don’t offer much, aside from tracking emails from FedEx and UPS (maybe). And when distributors have eager end-buyers asking when their order will arrive, they end up checking in on it themselves, which takes time.

“One of our team members said about 40% of her job is just following up on orders and checking tracking,” says Goltzman. “She can only do about half the orders she would be able to do because of all the follow-up, and that’s why we have multiple people on it. Sometimes we call and email and don’t hear back, even with a dedicated sales rep. When we’re not hearing back, we call them every hour and then every 15 minutes. That’s antiquated.”

Recently, a supplier assured Goltzman that the order would be delivered the following day, but he never received tracking confirming that. When he called to find out more, he was told the product would be late because it was stuck at port. “How would it have been decorated and shipped on time?” he asked them, without receiving a satisfactory answer. “And that’s with us checking up on it. I’d say 1% of suppliers are proactive with keeping us updated. Meanwhile, we’re fielding calls from our customers.”

In 2021, Goltzman says his company spent between $10,000 and $20,000 on courier services for those occasions when suppliers weren’t able to deliver on time. “It’s just the cost of doing business, because we’re not going to tell our customers they should hire their own courier,” he says. “Shrinkage is when we have to pay for an issue, and we’re trying to reduce that.” To that end, Goltzman says his company’s list of suppliers they work with has fallen from about 1,500 to approximately 300, based on the ease of doing business with them.

‘The Future Is Automation’

Throwing more people at the issues won’t solve them – staff shortages persist, making it more difficult to recruit, plus the time it takes for manual work to be done on processing and tracking orders adds to the holdups. Distributors – and suppliers – want to see more standardization and automation in the industry, where companies’ systems can communicate and process orders quickly.

“The future is automation,” says Goltzman, who adds that his team is happy to log in to suppliers’ platforms that provide easy-to-access updates. “Seeing exactly where an order is saves us a ton of time. And soon, no end-buyer will want to pick up the phone or send an email. But this industry is slow to adopt new technology. I still see so many people pick up catalogs at shows. Change takes time – we have to identify trends five to 10 years from now so we’re ready.”

The challenge, says Gergen, is all the different types of data that need to be processed, which makes communication among companies’ systems – and thus automation – exceedingly difficult at the moment. Agreement on standardization would help.

“Many distributors and suppliers in the industry think about their order and product data in different ways,” he says. “And not all companies have the IT infrastructure or support needed to implement standards and integrate them. Once the industry has agreed upon how to translate data, automation can increase at an escalated rate.”

The industry is full of different-sized firms, with varying levels of investment ability, says Chen, making standardized technology a challenge. It would require a majority of businesses to adopt it and be in harmony with each other, a big ask in a crowded industry.

“That’s just really hard to achieve given every company has to make its own decisions on where to spend limited resources to improve its own business and solve its unique challenges,” says Chen. “Also, there’s no guarantee of a rapid increase in sales volume, making it difficult for many companies to justify the spend.”

Norris says Starline is semi-automated in both production and order processing. It’s focused on automated machinery, so that screen printing equipment mixes inks correctly and the company isn’t required to train an operator on that action, for example. The supplier is also committed to developing a robust internal system that allows the team to process orders efficiently.

“PromoStandards pushes for peer-to-peer system communication,” he says. “Too often, suppliers are working on figuring out the correct shipping address and how to print labels when they should be focusing on order integration.”

Koozie Group, likewise, is working on addressing discrepancies in the information communicated, mainly by developing systems and data that other companies’ platforms can understand. “Focusing on this consistency allows us to interact with both technology and personnel to move orders efficiently and correctly through our systems to get the order decorated and shipped as quickly as possible,” says Gergen. “We’re looking at ways to make the order process better for both our customers and order processing team.”

The first step for automation to take hold is for the industry to agree on standardized systems so companies can communicate with each other. That process is a long one.

“Automation requires everyone to agree to all the steps,” says Cassidy. “In promo, we often struggle to agree because what works for me might not work for you. It often feels like we need to develop a new process with every new relationship.”

In the meantime, and as technology advances, Siegel says streamlining should start with a standard PO with required fields (which can’t be submitted until everything is filled out adequately), order checklists for both suppliers and distributors, and consistent onboarding. “It would be great if all of our platforms could communicate to each other and we could enter POs directly into their systems,” he says. “The tech still has to come a long way because there are so many moving parts.”

It pays for distributors to take advantage of the many features already available to them. “The industry needs to leverage the technology and capabilities that already exist in the hands of tens of thousands of sales and support staff,” says Andrews. “For instance, ESP has a Live Inventory feature – it’s as fresh as a phone call to a supplier or a visit to a supplier website. The data is available on 71,000 products, yet only a fraction of distributors click to check it. We’ll be doing more to make that front-and-center on the platform early next year.”

Distributors can also be better partners for suppliers, says Siegel. They should submit accurate POs that require little to no back-and-forth for clarification, and they should understand individual suppliers’ processes. “Also have an order checklist and follow up when you need to,” he says.

Gonzalez agrees about standardized POs, noting that she’ll call out her team when she sees incomplete submissions. She’d also be happy with automated emails letting them know where the order is in the process. “That’s a normal thing that should be happening,” she says. “They could even outsource it to other countries so we’re getting updates the next morning.”

Of course, as industry technology advances, another challenge will develop: balancing seamless ordering technology with maintaining value in end-buyers’ eyes as an industry of marketing expertise, not product-pushing. Gonzalez is optimistic that promo can be both and in fact, must be.

“We have to become more streamlined, but I don’t think we’ll ever get to the point where it’ll just be shop online and check out,” she says. “There’s too much customization and brand experience involved, and we’re challenged every day to offer that experience.”

So the question is: can the industry develop the necessary procedures and technology to be able to offer a smoother customer experience? Norris says promo has no choice but to continue improving the process. “If we don’t figure it out,” he says, “someone else will.”

Three ‘Magic Wand’ Wishes to Fix the Order Process

At our yearly work anniversary luncheon (a tradition here at ASI), Norman and Matthew Cohn ask each attendee for their one “magic wand” wish for the company or the industry. Well, to solve a problem as persistent and overarching as promo’s cumbersome order process, I’m going to need three, culled from my decade and a half in the industry and the countless extensive conversations I’ve had with our readers over the years. Got your own magic wand wish to solve the problem? Email me at cmittica@asicentral.com. – C.J. Mittica

1

Launch the “Common PO”

Applying to college was a long and tedious process – compounded by the fact that each school had its own lengthy application. So in 1975 a bunch of institutions got together and created the Common Application. Today, over 1,000 universities and colleges utilize the “Common App.” Now imagine the “Common PO” – a single all-encompassing purchase order that would simplify the confusion of dealing with so many different suppliers and address the glut of incomplete POs that put orders immediately behind the 8 ball.

2

Standardize the Exchange of Information

Data is like foreign currency – it has tremendous value, but is functionally useless if you’re in a place where nobody else can use it. That’s why digital integration is important. But it’s still a headache for distributors who rely on their own systems because they must individually (and tediously) integrate with suppliers (or vice versa with suppliers and distributors). Standardizing the flow of information opens the door for the things we’ve all been begging for: checking inventory, placing orders and then tracking shipments. A singular platform like ESP allows the industry to gather in one place to achieve those things, but at the very least, we need to speak the same language when it comes to data.

3

Make Space in Everyone’s Budget for Technology

I feel like this one is the most realistic. Businesses approach tech as this massive investment in both time and money that could revolutionize their operations but isn’t feasible for the small guys. In reality, both distributors and suppliers should leverage tech selectively and strategically to shore up weak spots and solve obvious inefficiencies. Want to expand your reach? Invest in e-commerce. Sick of spending so much time processing and tracking orders (time that could be spent making sales)? Dive into a cloud-based platform. Digital technology is available to everyone at a reasonable cost, and the sooner companies in our industry realize that, the quicker they can start adapting.