April 26, 2024

Apparel Company Creates Sustainable Embroidery Innovation

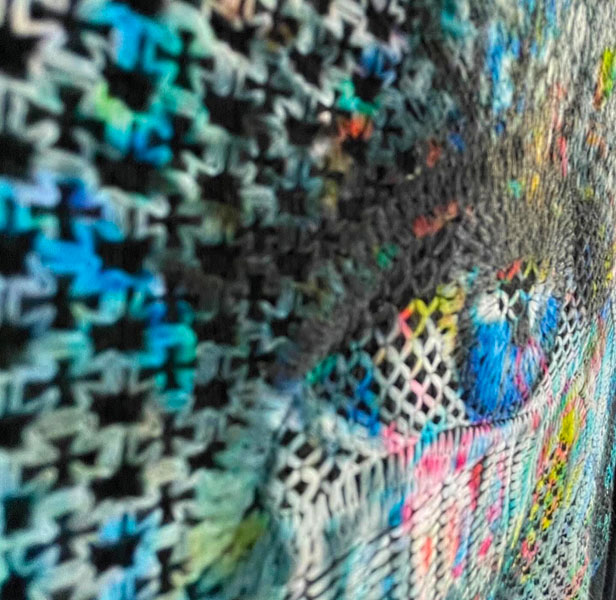

EC Clothing can create multicolored embroidery, with special effects like ombré, using a patent-pending process that infuses color into a clear fiber made of recycled materials.

Mark McNaught believes embroidery is ripe for a sustainable shakeup.

A founding partner of apparel company EC Clothing, creator of private-label brand Sea OceanS, McNaught and his company have developed a patent-pending process they call Photo Realistic Embroidery Technology (PRET). The technique involves using one clear thread – made from recycled PET fiber – that’s heated so it expands, allowing the company’s CMYK coloring system “to drip the correct color from our software directly into the fiber,” then it goes through a cooling system to lock in the color before being embroidered onto a garment or other substrate, McNaught says.

EC Clothing uses a sustainable embroidery technique that allows it to drip color directly into a clear thread before embellishing.

The system allows EC Clothing to make endless color changes in a design, using only one needle and one continuous fiber.

PRET is an innovation that’s similar to technology developed by Swedish company Coloreel, which manufactures a printer that does instant direct-to-embroidery thread dyeing, but McNaught says there are some key differences between the two.

The PRET technique is designed to be smooth on the top and bottom, with no backing required.

“What makes us different is that our process has a smooth finish on the top and underside of each garment,” McNaught says. “That means no backing materials are required. There’s no puckering, no shrinkage.”

Complex designs, with ombré color changes, can be executed on thin T-shirt material without creating a stiff, armor-like feeling that would result from more traditional embroidery methods.

EC Clothing’s technology can also create photorealistic portraits that can be embroidered into heat-seal patches.

“I can turn a garment inside out, and you’ll see the inside is the exact same as the outside,” McNaught adds. “A lot of people, once they see it and feel it, they’re like, ‘Oh my God, this is as light as the T-shirt. … The whole process is designed to be as light as the garment that it is being manufactured on.”

In its production facility in India, EC Clothing’s PRET equipment uses 26 feet of space and features 18 embroidery heads. The factory has 160 of the machines set up, allowing it to embellish 30,000 garments a day, according to McNaught. Right now, he adds, it wouldn’t be cost-effective for him to try to manufacture and sell the equipment to mom-and-pop decorating shops in the U.S. The embroidery technology also works best on the blank apparel that EC Clothing creates in-house, McNaught says, because the company spins its own triple-twisted recycled yarn and makes fabric that has “nonshrinkability” built-in.

“We take extra care and concern to the actual fiber, so that the end-user won’t have any shrinkage, puckering or the scratchiness that we’re all so accustomed to with traditional embroidery,” McNaught adds.

Promo for the Planet is your destination for the latest news, biggest trends and best ideas to help build a more sustainable and socially-responsible industry.