July 17, 2024

How Distributors and Suppliers Can Use Contract Decorators for Difficult Jobs

Promo firms that decorate in-house often outsource decoration jobs that might be expensive or require equipment that they don’t have in-house.

A good portion of promotional products distributors receive the products from the suppliers ready to ship. This means that the decoration has already been done, whether it’s screen printing, embroidery, laser engraving, or any of the other myriad ways to put a logo onto a product.

These suppliers, whether they’re manufacturing the products in-house or sourcing blanks, do much of the decoration legwork. But certain decoration techniques might be either more trouble than the company thinks is worth it or requires equipment that the supplier might not have or want to have on-hand. This is where contract decorators come into play.

“As with everything, the decision to outsource comes down to striking a balance that delivers the maximum value for your business and for your customers,” says Benjamin Adner, founder and chief innovation officer for Inkcups. “We work with many suppliers who are decorating products in-house with great success, but occasionally we see suppliers outsource to specialty decorators. This is usually because the decorator has some sort of technical capability that is not in their core competency – either it is for printing technology with greater speed or for multicolor digital capability.”

Adner specified that suppliers often outsource decoration for drinkware products, as they can be difficult to decorate in some instances.

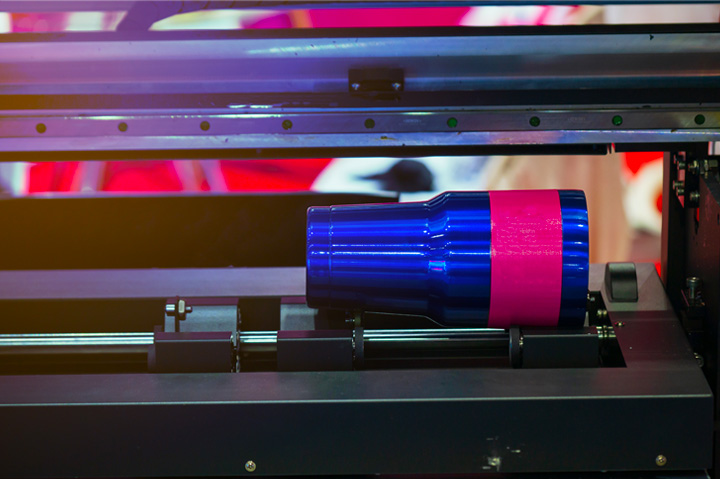

There are plenty of direct-to-object cylindrical UV inkjet printers available, but they might not be within a supplier’s budget.

“If your customers want high-end graphics or multicolor tight registration, and you’re not ready to make that investment or decoration simply isn’t part of your business model, then it would be advisable to work with a dedicated decorator who can offer digital drinkware decoration,” Adner says.

It’s not just suppliers either. Promotional products distributors looking to provide one-stop shops for their clients, or perhaps take advantage of print-on-demand capabilities to capitalize on pop culture moments, are decorating, too.

The Numbers Tell the Story

Among distributors in the U.S. and Canada who reported that they do some decoration in-house, 78% said they also use contract decorators for apparel, 84% said they use contract decorators for hard goods and only 12% said they don’t use contract decorators at all, according to ASI Research.

Among the specific products outsourced to contract decorators, decorators who decorate in-house and also contract out certain jobs reported these as the products they’ve outsourced to contract decorators in the last year:

The data backs up Adner’s claim: The most-commonly reported reason for outsourcing a decoration job was to perform a decoration technique they didn’t have the capabilities for in-house (80%). Additionally, 55% of distributors said they outsource decoration jobs that are too difficult to do in-house. Other factors included order sizes that were too big to handle in their own facilities, a turnaround time that they couldn’t meet in-house and a contract decorator being closer geographically to the end-buyer for decreased shipping costs.

Learning the Language

Like any business relationship, the communication between distributors or suppliers and their decorator partners is key for a smooth process. Adner says it’s crucial to keep an open line of communication with decorators not only to make sure that the order goes according to plan but to stay up-to-date on decoration techniques that they might not otherwise be aware of, but a dedicated decorator would be.

“We’re always surprised to meet people who aren’t yet aware of the extent to which direct-to-object digital inkjet printing can elevate the decoration of their products,” Adner says. “From drinkware to tote bags, UV inkjet printing can cost-effectively deliver vibrant full-color graphics in volumes as low as one. In addition to the tremendous design possibilities that enables, it also opens up possibilities for personalization, mass customization and on-demand production.”

Adner added that he simply loves when a customer asks how far their decoration capabilities can go. This could be using inks that they weren’t aware of to get different design effects on products or learning about different varnishes that they weren’t aware of.

From the customer perspective, in this case being a supplier or distributor outsourcing to a decorator, ASI Research found that they believe decorators could improve on three things more than anything else: faster turnarounds, better communication and better quality control. This means meticulous color matching for brand aesthetics, clear communication about what is possible and how quickly it can be done, and making sure that things are on time.

For suppliers, and even distributors looking to add different decoration techniques to their product offering and stay up-to-date on the technological capabilities to provide branded merchandise that might’ve been impossible – or at least much more difficult – to create just a few years ago, it’s not absolutely necessary to invest in a bunch of equipment right off the bat. Working with a contract decorator allows them to harness these new decorating techniques without having to invest in or master the equipment.