January 17, 2024

North Carolina Reclaims Its Apparel Heritage – With a Sustainable Twist

Once a global epicenter for clothing production, North Carolina is transforming its legacy by becoming a hub for apparel recycling and textile innovation.

An outdoor sports enthusiast with a keen interest in the natural world, Bill Johnston started his career in the mid-aughts, leading backpacking and mountaineering trips, incorporating a healthy dose of environmental education into every hike.

When he was ready to transition into the corporate world, he knew he wanted to further that focus on sustainability. And for a North Carolina native whose father ran a knitting mill, weaving a thick thread of sustainability into the apparel industry was a natural fit. Johnston became curious about the technology behind creating recycled cotton and polyester fabrics; at the time, he said, those materials were mainly used in products like carpeting, and companies weren’t advertising their use, viewing their reused nature as more of a stigma than a selling point.

But Johnston saw potential. “I was fascinated,” he says, “and felt like there was an opportunity to turn it into a story and create a brand around it.”

With the help of a family friend – who had been selling his father’s yarn for decades – Johnston launched Recover Brands, a boutique sustainable apparel company that uses 100% recycled or organic materials in every product and operates with a closed-loop manufacturing process. Recover began as a side hustle, but Johnston was full time with the company he’d created by 2012. More recently, Recover became a part of NG Labs, which also owns Boxercraft (asi/41325), and has been making a bigger push into the promotional products space.

“It’s really advantageous for us to be [in North Carolina]. There’s so much experience and wisdom here from a textile standpoint.” Bill Johnston, Recover Brands

As Recover has grown and moved into other regions – with distribution in Atlanta and production in Central America – North Carolina has remained integral to the fabric of the brand. “It’s really advantageous for us to be here,” Johnston says of the state. “There’s so much experience and wisdom here from a textile standpoint.”

Textile mills moved into North Carolina in the early 1800s, and by the mid-1900s, the state had become a hub of U.S. textile manufacturing. In the 1990s, according to an article in Business North Carolina magazine, there were textile and apparel mills in every county, with 2,000 companies employing nearly 280,000 textile and apparel workers. But the push toward globalization – along with the passage of free trade agreements like NAFTA in 1994 – took a toll on the state’s textile manufacturing sector that’s still reverberating today. Just last year, for example, Top 40 supplier Gildan (asi/56842) closed a yarn-spinning plant in Salisbury, NC.

Still, North Carolina has been undergoing, if not a full revival, a renaissance of sorts. Today, the state exports around $1.4 billion in textile goods each year, leading the nation with nearly 20% of all U.S. textile exports and employing more than 39,000 people, according to the Economic Development Partnership of North Carolina (EDPNC), a nonprofit public-private partnership devoted to job creation and investment in the state. A variety of factors (proximity to cotton cultivation, a concentration of high-end research and development, legacy expertise and a residual manufacturing infrastructure) are turning it into a breeding ground for apparel innovation, textile recycling initiatives and sustainable clothing startups – with industry often bursting, phoenix-like, from facilities and equipment that manufacturers had abandoned in years past.

The Sustainable Benefits of Made-in-the-USA

Pilot Mountain, NC-based Sports Solutions (asi/88876), which makes custom socks, sweatbands and other products, operates out of a former hosiery mill that closed in 1989. The supplier moved into the 36,000-square-foot vacant building in 2013. “It wasn’t falling apart, but it needed some major TLC,” says Charles Badgett, owner of Sports Solutions, adding that he was committed to building a successful business in his home state.

Sports Solutions still uses some of the older hosiery machines in production, noting on its website that there’s “nothing that can replace the quality of an older knitting machine.”

Though domestic manufacturing has its challenges, it also gives Badgett the benefit of “complete control.” He adds: “I have the material for everything right under my nose. I don’t have to worry about some guy I’ve never met in my life across the world that I’m putting my customers’ trust in.”

There’s also an element of sustainability that comes with Made-in-the-USA products. “From an environmental standpoint, carbon reduction is one of the biggest things, and a lot of that’s just associated with transportation,” Johnston says. By concentrating production in North Carolina, “you’re not shipping stuff back and forth across the world.”

Recover Brands, part of NG Labs, does about one-quarter of its production in the American southeast, near its North Carolina headquarters.

Recover Brands does about 25% of its production in the American southeast, with its Made-in-the-USA products all created within a 250-mile radius of its North Carolina headquarters, according to Johnston. The rest of its production is nearshored in El Salvador at a vertical manufacturing facility where every step of the supply chain – from spinning recycled fibers into yarn to sewing the finished garment – is done under the same roof.

Centering textile production in North Carolina has the benefit of being close to where the cotton is grown, says Eric Henry, owner of TS Designs, a B Corp-certified screen printer based in Burlington, NC, who has been an advocate for Carolina-made apparel for decades.

“We’re essentially at the intersection of agriculture and apparel; we’re the sweet spot,” Henry says, noting that North Carolina is basically the northernmost locale in the U.S. that can grow cotton. “We’re just very fortunate that we’re able to grow cotton here and we’re able to connect those dots.”

TS Designs began life as a large-scale contract screen-printing business for big brands but was forced to reevaluate its model in the 1990s when its customers started going overseas. “We decided that we could do it here,” he says. “We never left.”

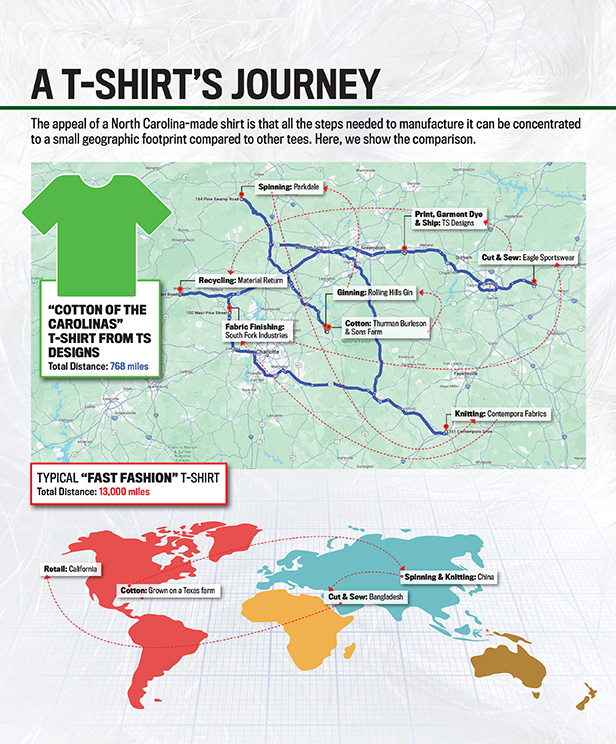

The apparel decorator developed a transparent and trackable supply chain, adding a QR code to the neck label of tees that, when scanned, details every link of the chain, back to the farmer that grew the cotton. Every step, from “dirt to shirt,” in the process of its “Cotton of the Carolinas” tee happens within 768 miles (as opposed to a conventional tee that can travel 13,000 miles or more during its creation; see the sidebar “A T-Shirt’s Journey” at the bottom of the article).

“Regional sourcing is a win,” says Meredith Boyd, senior vice president of technology, innovation and sustainability at Greensboro, NC-based fiber maker Unifi. “You’re moving goods over a shorter distance, and you’re also empowering companies to look at their own responsible use of resources because they’re not having to anticipate shipment times.”

Carolina’s Circular Economy

Unifi manufactures recycled polyester (rPET) brand Repreve, which is used in a variety of promotional products from quarter zips to reusable grocery totes. In fiscal ’22, Repreve sales represented 36% of Unifi’s overall fiber sales, according to Boyd. Repreve production occurs in two of the global company’s North Carolina plants. In Reidsville, NC, Unifi operates its Repreve bottle recycling center, where it collects and processes plastic bottles into flake. A little over an hour west in Yadkinville, NC, the flake is transformed into resin and then melted down into filament at the company’s yarn facility, Boyd says. “The yarn is texturized, roughed up, made into a nice and soft and fluffy textile yarn product that can replace any virgin polyester,” Boyd says.

Discarded single-use plastic bottles are processed into polyester fiber at Repreve’s recycling facility in North Carolina.

There’s debate in sustainability circles over whether recycled polyester is greenwashing and not actually a sustainable textile choice since it doesn’t stem the tide of production of single-use plastic bottles, and recycled polyester has been shown to shed more microplastics than virgin polyester. However, Boyd notes that Unifi looks at it from a “waste hierarchy standpoint,” promoting reduction and reuse first and foremost, but acknowledging the reality that waste exists and needs to be dealt with. “We need to be a steward and determine how we can make use of it, and polyester is the world’s largest fiber going into textile applications,” Boyd says.

North Carolina is also pivotal in closing the loop on cotton textiles. Recover Brands, Johnston says, works with Material Return, a Morganton, NC-based company that can take post-consumer garments, grind them into fibers, which can then be remade into new clothing. Founded in 2017, Material Return notes on its website that it processes millions of pounds of textile and furniture waste each year and transforms it into ReturnTex, a yarn made from the region’s waste in a hyper-localized supply chain of 75 miles.

Material Return – part of The Industrial Commons, a western North Carolina incubator for employee-owned social enterprises and industrial cooperatives – helps a variety of businesses in the circular economy.

Last year, Material Return announced that it had created the “first circular socks,” thanks to an ongoing partnership with Smartwool. The company received over 750,000 socks through Smartwool’s ongoing consumer take-back program and helped the brand launch its Second Cut hike sock. The collected socks were shipped to Leigh Fibers in Welford, SC, to be ground, then shipped back to Material Return to be transformed into a raw material input, which was spun into yarn at the Textile Technology Center at Gaston College, then blended with merino wool from Chargeurs Wool in Jamestown, SC. The yarn was shipped to Renfro Corp. in Cleveland, TN, to be knit into socks, which were tested at the Manufacturing Solutions Center in Conover, NC.

“As so many global apparel brands are seeking more environmentally sound production methods, Material Return and our community of partners are leading the charge when it comes to true U.S.-based circular production,” says Bob Carswell, Material Return research and development director. “This breakthrough shows that there’s a better and scalable way to manufacture clothes, and that the global apparel industry can eliminate waste and create truly sustainable life cycles for their products.”

Research, Development & Innovation

North Carolina has also been at the forefront when it comes to research and innovations, from locally sourced natural dyes to cutting-edge sustainable textile technology.

TS Designs has been experimenting with garment dyes derived from a variety of natural materials. In 2022, Henry collected hundreds of pounds of walnuts that fell from trees near his home, then partnered with a local brewery, Burlington Beer Works, which cooked the walnuts to create a soft brown dye. The dyeing process from “ground to garment” took about 48 hours, according to TS Designs. The decorator has also created other small-batch natural dyes. Madder root and fustic extract, for example, turned into unique earthy orange patterns for limited-edition tie-dye designs on its own Solid State Clothing line. “It’s very small scale, but we want to build scale,” Henry says of his company’s natural dye efforts.

Through Solid State Clothing, TS Designs recently introduced a North Carolina-grown cotton tee dyed a pale yellow from hemp leaves grown at a farm in Warren County, NC. It’s the first American T-shirt brand to use hemp leaves for dye.

Solid State Clothing, an apparel brand made by Burlington, NC-based B Corp TS Designs, created this cotton tee, garment dyed with hemp leaves grown in North Carolina.

Hemp, which has been legal to cultivate commercially in the U.S. since the 2018 Farm Bill passed, is on the horizon as an apparel textile input as well. Hempsmith, an apparel decorating shop in Pittsboro, NC, has been selling custom hemp clothing for the last few years in an effort to grow awareness and build a market for the fiber, says owner Arlo Estill. Right now, he’s importing hemp because the domestic hemp market is still in its infancy, but the goal is to use American-grown hemp in the future. “If we can demonstrate that there’s a real demand for hemp textiles, then that’s going to allow farmers and processors to invest more and build out the infrastructure that’s needed,” Estill says.

He believes North Carolina will play a pretty big role in building that infrastructure, thanks to work being done by institutions like North Carolina State University’s Wilson College of Textiles and the Carolina Textile District, working with local agriculture. Over the summer, in fact, the Wilson College of Textiles hosted an executive roundtable to talk about the industry’s efforts to scale up sustainable textile-grade hemp production in the U.S.

Henry also sees a lot of upsides: “I think hemp is going to be great because it plays well with cotton. It adds strength, durability and some antimicrobial properties.”

Sustainability-focused designer Stella McCartney used seaweed-based Kelsun fiber from Keel Labs to create this knit dress.

Hemp isn’t the only sustainable fiber making headlines in North Carolina. Keel Labs, a textile startup headquartered in Morrisville, NC, created a kelp-based fiber called Kelsun that designers like Stella McCartney are using to create knitwear and other high fashion pieces. “One of the very cool things about seaweed is that it uses significantly less fresh water than cotton in production, which is a really big deal. It also uses zero agricultural land, so we’re not displacing nature in order to create fields of seaweed,” says Lysandra Weber, marketing manager for Keel Labs. “It can all grow in saltwater, and seaweed grows incredibly fast.”

North Carolina, Weber says, was an ideal location for Keel Labs’ headquarters because of the state’s textile-rich legacy but also because there’s a robust brain trust of STEM professionals in the region. Weber adds: “It’s like this perfect merging of biotechnology and fashion in one place.”

Promo for the Planet is your destination for the latest news, biggest trends and best ideas to help build a more sustainable and socially-responsible industry.